Steinmüller Africa’s specialised induction bending solutions supports schedule-driven projects

Submitted by: CubicICE Save to Instapaper

Steinmüller Africa holds the only Cojafex PB 850 induction bending machine in Africa. The machine was purchased in 2010 and to date, has conducted over 6 300 induction bends on a local and international scale at their 30 000 m2 manufacturing facility at Pretoria. Induction bending reduces the number of field welds, expedites construction and optimises project schedules. The cost and complexity of long-term maintenance is improved by reducing the number of welds that require regular inspections. Complex 3-dimensional bends are the real benefit of using induction bends in pipeline systems.

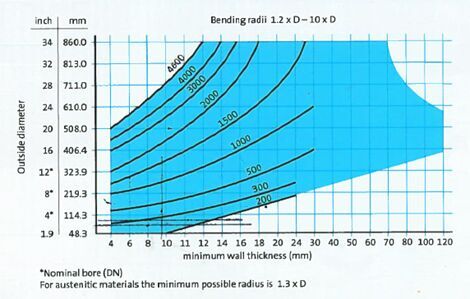

The machine can bend pipes with a minimum outside diameter of 48.3 mm and maximum of 870 mm, and a minimum wall thickness of 4 mm and a maximum of 120 mm. Thicker walls can be considered, pending specific technical details.

Steinmüller Africa offers its service to the paper and pulp, power, petrochemical, mining and metallurgical industries. Induction bending is especially beneficial for high-pressure (HP) piping, steam piping and industrial piping systems. Steinmüller Africa has almost ten thousand welding procedure specifications across a wide range of alloy materials. The company is a specialist service provider across the fields of welding, environmental technology, manufacturing, maintenance, lifetime extension plans and project management.

CubicICE offers you the full range of digital marketing, public relations and creative design services to execute marketing strategies tailored to your business requirements. Our speciality is in producing content that engages engineers, manufacturers, procurement officials and distributors through effective marketing channels; in transforming the unique technical details of your products and services into compelling, powerful marketing campaigns. Our team combines innovation, creativity, knowledge and production skill with a strong customer focus to ensure maximum ROI from your marketing spend. Automotive, mining, construction, manufacturing, energy, plant and factory automation, material handling, petrochemical, oil and gas, ICT, warehousing and logistics, packaging, electronics, engineering and water treatment - these are just some of the many industries we've been involved in over a marketing legacy that spans more than 30 years and over 200 clients. Get in touch with us today to see how we can help you grow your business!

Latest Press Articles

- Steinmüller Africa’s drone technology cuts maintenance and repair costs

- Steinmüller Africa integrates advanced technologies at Mondi’s Boiler Erection Project Vuselela

- Steinmüller Africa achieves 51 000 X-ray quality butt welds in power generation milestone

- Steinmüller Africa receives six awards at Eskom Welding Awards 2024

- Pretoria Workshop Delivers First-Of-Its-Kind Pulverised Fuel Burner Openings Assembly for Duvha Power Station

- Hytec South Africa Donates Safe Sanitation Facilities to ECD Centre in Pietermaritzburg

- Bosch Rexroth Africa’s Training Department Launches Cutting-Edge Modular Training Workstation

- Hytec Engineering and Power Team Collaborate on Innovative Water Tank Project

- Hytec South Africa Opens 15th Mandela Day Library at Limpopo School

- Steinmüller Africa’s Submerged Arc Welding Ensures Clean, High-Quality Welds

- Alex Booth Appointed Director of African Operations at Bosch Rexroth Africa

- Bosch Rexroth Africa Announces Retirement of Esteemed Group COO, Mike Harrison

- Steinmüller Africa Invests in Education at Two Mpumalanga Schools

- Experienced Leader Nick Boddy Joins Hytec South Africa as Branch Manager

- Hydraulic & Automation Warehouse Revitalises Partnership with KTR Systems

The Pulse Updates

- Timeless, Bold, And Distilled With Care - Just Like Dad (June 2, 2025)

- New Report Reveals Msme Funding Realities In South Africa – And What Must Change (May 30, 2025)

- Opinion Piece: Incorporating Ai Into Workforce Planning (May 26, 2025)

- Bridging The Gap: Why Finance And Hr Must Collaborate For Business Success (May 19, 2025)

- Reclaiming Johannesburg’s Running Narrative Powered By The Streets. Refreshed By Pura. (May 16, 2025)