Hytec enters partnership agreement with GS-Hydro

Written by: CubicICE (PTY) Ltd Save to Instapaper

Hytec South Africa, a Bosch Rexroth South Africa Group Company, and GS-Hydro, an Italy-based multinational non-welded pipe manufacturer, have entered into a non-exclusive partnership agreement. Effective 01 November 2018, the partnership endorses Hytec South Africa as a sub-Saharan Africa distributor for all GS-Hydro components and piping systems above 42 mm.

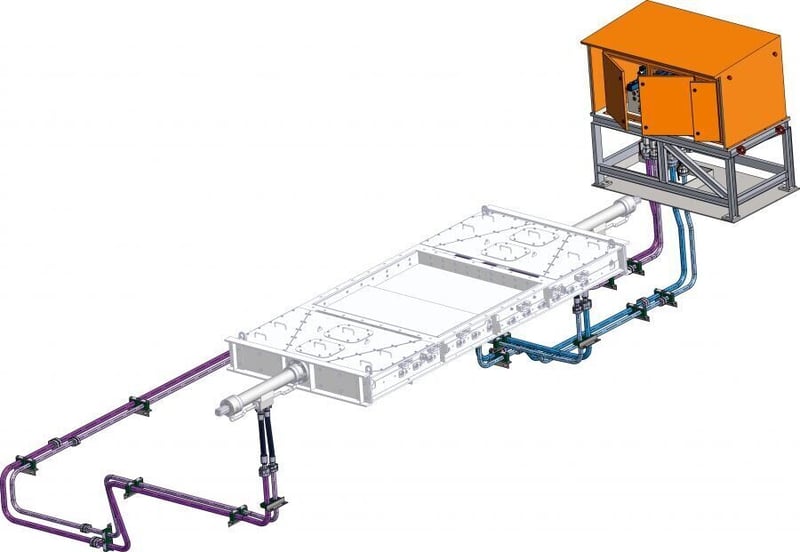

The distributorship increases Hytec South Africa’s product and service capabilities and presents new opportunities for distributing non-welded, leak-free piping systems. This is especially the case where projects include design and engineering, as GS-Piping Systems’ assemblies can be prefabricated to a high degree prior to installation, which speeds up the installation process and reduces overall costs.

Cost savings through the lifetime of the piping systems are gained because there is a lower total installed system cost, a shorter installation time, less flushing time and reduced need for maintenance and repairs. “These benefits lead to fewer production interruptions and much shorter downtime when interruptions do occur,” points out Hytec South Africa Engineering Manager Andre Lindeque. “The GS-Piping System’s flexibility facilitates fast and easy installation which translates to significantly lower installation costs when compared to a welded piping system.”

The superior technology used, which provides the high-quality, leak-free piping system, is approved by classification agencies. The environmentally friendly pipes provide consistent quality due to machined and prefabricated assemblies, are suitable for different materials and offer the highest level of cleanliness. “As there is no welding involved in manufacturing these pipes, there is no need for post-weld cleaning or costly weld inspections such as x-raying,” Lindeque explains.

All GS-Hydro products have a 12-month warranty, which Hytec South Africa upholds, and is also equipped to handle all maintenance and repairs.

Hytec South Africa currently has GS Hydro Flaring and Bending Machines in use at its premises. The Flaring Machine provides 37° flaring with the capacity of flaring pipe sizes from 6 to 170 mm, and the bending machine has the capacity to bend pipes sizedfrom 16 x 2 mm (wall thickness) up to 60 x 6 mm (wall thickness.) Depending on the outside pipe diameter, the bend radius provided is either 2.5 or 3.0.

GS-Hydro is the world’s leading supplier of innovative, non-welded piping solutions for hydraulic and other low and high pressure applications with high demands on quality, reliability and cleanliness. GS-Hydro is the original provider of non-welded piping solutions and relies on more than 40 years of experience in the field.

The non-exclusivity part of the agreement with Hytec South Africa pertains to GS-Hydro’s other sub-Saharan Africa partner and distributor, Hägglunds Drives South Africa – which is also one of Hytec South Africa’s sister companies.

CubicICE offers you the full range of digital marketing, public relations and creative design services to execute marketing strategies tailored to your business requirements. Our speciality is in producing content that engages engineers, manufacturers, procurement officials and distributors through effective marketing channels; in transforming the unique technical details of your products and services into compelling, powerful marketing campaigns. Our team combines innovation, creativity, knowledge and production skill with a strong customer focus to ensure maximum ROI from your marketing spend. Automotive, mining, construction, manufacturing, energy, plant and factory automation, material handling, petrochemical, oil and gas, ICT, warehousing and logistics, packaging, electronics, engineering and water treatment - these are just some of the many industries we've been involved in over a marketing legacy that spans more than 30 years and over 200 clients. Get in touch with us today to see how we can help you grow your business!

Latest from

- Steinmüller Africa’s drone technology cuts maintenance and repair costs

- Steinmüller Africa integrates advanced technologies at Mondi’s Boiler Erection Project Vuselela

- Steinmüller Africa achieves 51 000 X-ray quality butt welds in power generation milestone

- Steinmüller Africa receives six awards at Eskom Welding Awards 2024

- Pretoria Workshop Delivers First-Of-Its-Kind Pulverised Fuel Burner Openings Assembly for Duvha Power Station

- Hytec South Africa Donates Safe Sanitation Facilities to ECD Centre in Pietermaritzburg

- Bosch Rexroth Africa’s Training Department Launches Cutting-Edge Modular Training Workstation

- Hytec Engineering and Power Team Collaborate on Innovative Water Tank Project

- Hytec South Africa Opens 15th Mandela Day Library at Limpopo School

- Steinmüller Africa’s Submerged Arc Welding Ensures Clean, High-Quality Welds

- Alex Booth Appointed Director of African Operations at Bosch Rexroth Africa

- Bosch Rexroth Africa Announces Retirement of Esteemed Group COO, Mike Harrison

- Steinmüller Africa Invests in Education at Two Mpumalanga Schools

- Experienced Leader Nick Boddy Joins Hytec South Africa as Branch Manager

- Hydraulic & Automation Warehouse Revitalises Partnership with KTR Systems

The Pulse Latest Articles

- Xlink: An Avant-garde, Purpose-driven Fintelco Driving Digital And Payments Interoperability On The African Continent (August 1, 2025)

- Success Is Just The Beginning For This South African Brand (July 31, 2025)

- Embassies Business Fair And Conference 2025 To Fast-track Africa’s Global Economic Integration (July 31, 2025)

- There Is A Small Business Funding Readiness Crisis In South Africa (July 30, 2025)

- Young Achievers Shine At The Top Of The Growthpoint Gems Class (July 30, 2025)