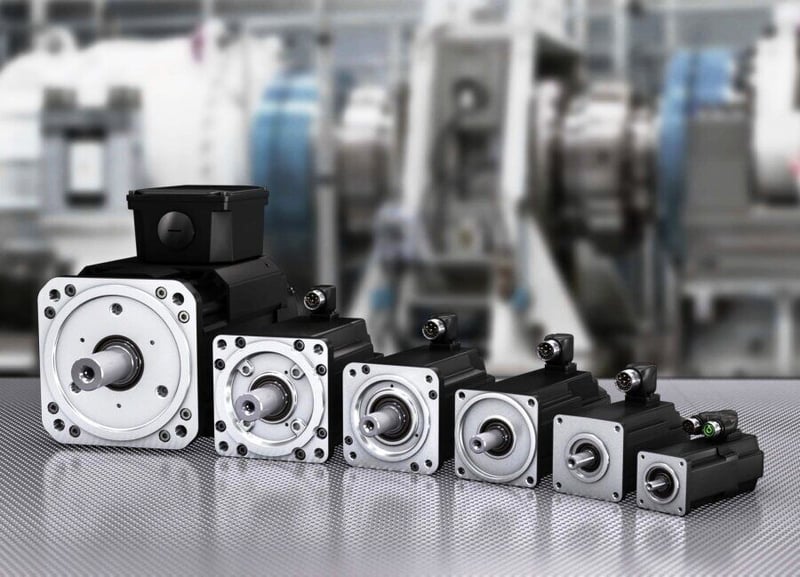

New synchronous motor generation from Bosch Rexroth - intelligent, powerful and flexible

Written by: Parusha Save to Instapaper

Bosch Rexroth meets intelligent solutions combined with short cycle times and flexibility in the market requirements of the Industry 4.0 environment with the newly-designed MS2N synchronous servo motor product line. The MS2N product line is available throughout sub-Saharan Africa exclusively through Tectra Automation. The product line covers the maximum torque range between 4 Nm to 350 Nm with significantly increased power density and greater energy efficiency. In association with IndraDrive control devices, MS2N motors are becoming the source of data for tasks within the networked production plant.

With this in mind, Bosch Rexroth has opened up completely new application opportunities and has set new standards in servo drive technology. The MS2N product line is tailored to the demands of the future in both functionality and performance.

Individual readings of every single motor, as well as the saturation and temperature data, are deposited into motor data storage and automatically processed by IndraDrive control devices. This increases torque precision significantly and reduces the tolerance range during operation to a fraction of the values that have been standard up to now. For the first time, the servo motor can be used as a reliable sensor, as well as a data source. In this way, applications within the Industry 4.0 environment, like condition monitoring, can be realised cost-effectively and without additional components.

Up to 30% higher torque density

The motors are significantly more compact despite their higher performance. With a new motor construction, and optimised electromagnetic design, this new generation of motors achieves up to 30% higher torque density. This has two effects for machinery manufacturers; smaller motors can be employed for current drive tasks while more performance is available within the prescribed motor clearance. The up to five-time overload capacity with persistently low rotor inertia guarantees the greatest possible acceleration and dynamics in all sizes. Thanks to high-grade materials, this new development also makes it possible to have continuous output within higher rpm ranges, and along with optimised winding technology, it also reduces internal losses. In the process, the new generation of motors achieves significantly improved energy efficiency and provides a sustainable reduction in operating costs.

Up to 75 metres with one cable

The highly dynamic MS2N product line comes in six sizes, with up to five lengths available in each. The product line covers the 4 Nm to 350 Nm maximum torque performance range and the 0.8 Nm to 148 Nm permanent torque performance range. Alternate variations with higher rotor inertia for better mass-customisation compliment this extensive range and allows for precise alignment of task formulation and motor selection. There are three corresponding, differentiated encoder systems.

To supply power and the encoder signal, Bosch Rexroth provides an innovative single-cable connection, as well as conventional two-cable solutions, with highly flexible cable variations and a practical quick lock. Both options enable a complete cable length in the IndraDrive standard, which means up to 75 meters with no additional components is possible. In this way, both types of connections can be combined with one another at minimal cost. The equipment wiring is no longer subject to the limitations of previous single-cable systems.

Tectra Automation, a Hytec Group company, is a leading drive control specialist providing solutions for industrial and factory automation applications.

Get new press articles by email

Latest from

- FactoryTalk AssetCentre Software Simplifies Life-Cycle Management, Automates Asset Discovery

- Discover how Manitou meets market demand with customer-centric focus at EMA 2016

- Ingersoll Rand launches Compressed Air Rental Services helping customers achieve maximum production and minimum downtime

- Continental Presents its Product Portfolio for the Mining Industry at Electra Mining Africa 2016

- Veolia installs sewage treatment plant for CLN Nacala Corridor Project, Mozambique

- Hytec Group and Bosch Rexroth join forces at Electra Mining Africa 2016

- Jury and prize revealed for ‘Best Future Machine Award’ at interpack 2017

- Rockwell Automation strengthening its roots in Africa

- CompactLogix 5380 Controller Improves Accuracy and Performance of High-Speed Applications

- APC Storage Solutions SA launches one new automated storage system each year

- Veolia helps protect wetland with sewage plant upgrade

- HAW adds compact cast iron gear pumps offering 19 000 configurations to its distribution range

- Veolia supplies water treatment plant to Ghanaian Power Plant

- Rockwell Automation supplies control system for one of KwaZulu-Natal’s largest water infrastructure project

- Veolia pilots a process to optimise biogas production in Durban

The Pulse Latest Articles

- Life Doesn’t Have To Be A Lot – The In-between Drink (February 17, 2026)

- Opinion Piece: Activating Leadership To Engage The Passive Workforce (February 11, 2026)

- Tchagra Trail Wilderness Consulting Launches A New Safari Experience In Photography And Tracking (February 9, 2026)

- Magic: The Gathering Releases Lorwyn Eclipsed (February 6, 2026)

- Back To Work, Back To Balance: Rethinking The 3pm Slump (February 5, 2026)