POLYSTYRENE ASSOCIATION LAUNCHES FOOD COMPLIANCE RESPONSIBILITY INITIATIVE (FCRI)

The Polystyrene Association of SA has launched a Food Compliance Responsibility Initiative (FCRI) - aimed at ensuring that world-class health and safety standards are adhered to in the South African context. Members of the Association who manufacture packaging used in food contact applications have been encouraged to sign a voluntary commitment to adhere to international health and safety standards.

Polystyrene (PS) packaging is widely used by brand owners, retailers and the fast food industry to sell a wide variety of different food products. Yoghurt cups, drinking cups, ice-cream containers and fresh fruit trays, meat trays, poultry trays and convenience food boxes are all made from PS. The packaging is strong, light and stable. It increases the shelf life of food, keeping it fresh and making it easy to transport and store. “These are all excellent product qualities which have made PS the material of choice for many applications. However, as with any other packaging material, it needs to be used as intended by the manufacturers and handled correctly - especially in certain phases of its life cycle if it is to have a role in a sustainable future for society,” explains Adri Spangenberg, CEO of the Polystyrene Association of SA.

Adri goes on to clarify that the driving force behind the initiative is the belief that raw material suppliers, product manufacturers, product distributors and consumers are joint stewards for the responsible and sustainable production and use of food compliant PS products. “Manufacturers are required to ensure that all raw materials included during the production process, are food grade certified. Good manufacturing practices must be displayed at all times and only in-house recyclate derived from the original food grade raw materials is allowed to be used,” she says.

Support from the industry has been very positive and welcoming and the country’s biggest manufacturers of polystyrene packaging have already committed themselves to these standards. “We are very excited about this recent development and believe it will it is an important step forward that will protect the growth and well-being of our industry and ensure the long-term use of polystyrene as the packaging material,” Adri concludes.

POLYSTYRENE ASSOCIATION RESPONDS TO DEA LABEL OF “PROBLEM PLASTIC”

“It is an excellent product that gets the job done. The problem does not lie with the material, but with how it is discarded and highlights the need for waste infrastructure to be developed. We believe we have a viable solution to this problem…”

The Polystyrene Association of South Africa (PolySA) has responded to a statement made by the Portfolio Committee on Environmental Affairs before the National Assembly yesterday, that polystyrene is one of the five so-called “problem plastic products” that have a short lifespan and are the biggest culprits in our environment. The other items on this list are plastic cutlery, stirrers, earbuds and straws.

The Association’s Chief Executive Officer, Adri Spangenberg, said that polystyrene is so much more than just a single-use plastic, given the fact that South Africa has developed various end-markets that use recycled polystyrene with great effect.

“During the 2017-2018 financial year, more than 6 300 tons of polystyrene were successfully diverted from our country’s landfills and recycled in South Africa. Considering that our recycling figures stood at 1 849 tons in 2013, we are very proud of this growth – proving that the local polystyrene recycling industry is growing and thriving,” she said.

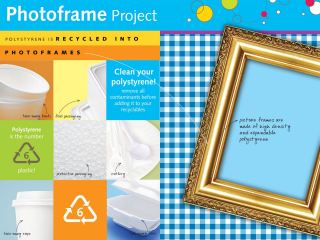

Spangenberg said recycled polystyrene is in great demand by recyclers, who use the material in the production of picture frames, cornices and stationery. “The biggest demand for polystyrene, however, has comes from the building and construction industry where recycled polystyrene is used in the production of lightweight concrete bricks and screeds. Polystyrene used in this application can be of any colour or grade, clean or slightly contaminated as it gets chopped up and mixed with a special mixture of cement and other ingredients to form lightweight concrete that is waterproof, fire resistant, offers insulation against heat and cold and it is cheaper and easier to build with than traditional bricks or concrete”.

The Association acknowledges that polystyrene is one of the items frequently found in the environment, owing to the fact that it is incredibly lightweight and is therefore easily scooped up and blown away by the wind.

“94 % of polystyrene is air, and only 6 % is product. This gives polystyrene the reputation of being “engineered air” that has the lowest carbon footprint of all packaging materials, in addition to being affordable. It protects valuable goods and food from breakage or spoilage and is an excellent insulator for hot or cold foods and beverages. In short, it is a material that gets the job done. The problem therefore does not lie with the material, but how it is discarded after use. In our opinion, this highlights the need for proper waste management infrastructure to be developed and implemented by municipalities around the country,” Spangenberg stresses.

The Department of Environmental Affairs agreed that the country cannot afford a knee-jerk reaction to problematic single-use plastics and has called for a thorough socio-economic impact assessment to measure the effect that alternatives to these problem products will have on the industry, consumers and jobs.

“The plastics industry provides employment to more than 60 000 people and the Polystyrene Association has recently unveiled exciting plans that will see this figure increase even further. We are partnering with municipalities to take polystyrene collection and recycling to the people with the establishment of Polystyrene Trading Hubs in the larger metro cities and Municipal Polystyrene Recycling Hubs in outlying areas. These hubs will address will provide a much-needed solution for housing, employment and the waste crisis by enabling communities to collect, recycle and produce the material they need to address the build houses in their immediate area”.

Projections are that polystyrene recycling in South Africa will be increased by to 63.7 % (27 870 tons) per annum by 2023 with these hubs.

“Banning polystyrene just as we are on the cusp of an exciting breakthrough, will jeopardize the future employment of thousands of people and undermine the excellent work we have been doing over the last 11 years. Our industry is committed to finding a solution that will permanently bring an end to plastics polluting the environment. We invite Government and other stakeholders to engage with us in the weeks and months to come as we work together to find what we believe can undoubtedly be a win-win solution that the rest of the world can follow,” Spangenberg concluded.

For more information, visit www.polystyrenesa.co.za

South Africans Urged to Recycle their Polystyrene

What is white, light, considered of high value and, although made up almost entirely of air, is in very high demand? If you guessed polystyrene, you’d be 100% correct!

According to Adri Spangenberg, Director of the Polystyrene Association, expanded polystyrene is one of South Africa’s most commonly used materials relied upon by canteens and spaza shops owners and restauranteurs to keep their food or beverages hot or cold, as well as by retailers to protect high value items such as televisions or fridges owing to the material’s excellent insulation properties.

“Polystyrene, also known as Styrofoam, is also widely used by supermarkets to transport and pack their perishable food products such as meat, fruit and vegetables owing to the fact that polystyrene offers excellent insulation properties, extends the shelf life of food and protects its contents thus reducing spoilage or damage,” she explains.

Polystyrene consists of 96% air, which makes it incredibly lightweight. Whilst it is a positive attribute that greatly reduces carbon emissions during transportation, it also causes polystyrene products to easily be blown away by wind where it becomes visible litter found on beaches or along roadsides.

“Few people are aware that polystyrene is a valuable resource that is readily recycled in South Africa. Waste Management companies collect and supply post-consumer and post-industrial polystyrene products such as meat trays, hamburger clamshells and coffee cups to recyclers who use it to manufacture stationery, hangers, picture frames, cornices, curtain rods and skirtings. “In the most recent development it is mixed with a special cement mixture for use in building and construction,” Adri states.

Because of the development of these end-markets, the demand from recyclers currently outstrips the supply of the materials. To this end, South Africans are urged to remember to include their polystyrene into their clear recycling bags to prevent this valuable resource from ending up in landfills. Please remember to scrape or rinse your polystyrene before recycling it to ensure that all food left-overs have been removed. Recyclers readily accept all colours of products, including white, black, blue, yellow and pink.

“Polystyrene recycling has grown year-on-year to more than 4 200 tonnes last year, saving 162 350 000 litres of landfill space thanks to the various recycling projects. This is equivalent to 65 Olympic-sized swimming pools filled with polystyrene that was diverted from landfill, that at the same time helped to create more than 48 000 jobs in the plastics recycling industry. We are working tirelessly to ensure that recycling remains at the top of everybody’s environmental agenda and to raise awareness about the value of recycled polystyrene,” Adri concludes.

For more information about polystyrene recycling, visit www.polystyreneassociation.co.za

Polystyrene Recycling takes off in PE and Durban

What is white, light, considered of high value and, although made up almost entirely of air, is in very high demand? If you guessed polystyrene, you’d be 100 % correct!

The Polystyrene Association of South Africa has teamed up with Wildlands in Durban and Rhino Greenbuilding in Port Elizabeth to collect, process and supply post-consumer and industrial recycled polystyrene products to manufacturers - ultimately offering a solution that will prevent this valuable resource from ending up in these two cities’ landfill sites.

“Expanded polystyrene is one of South Africa’s most commonly used materials relied upon by canteens and spaza shops owners and restauranteurs to keep their food or beverages hot or cold, as well as by retailers to protect high value items such as televisions or fridges owing to the material’s excellent insulation properties,” explains Adri Spangenberg, Director of the Polystyrene Association of South Africa.

Polystyrene is widely used by supermarkets to transport and pack their perishable food products such as meat, fruit and vegetables owing to the fact that polystyrene offers excellent insulation properties, extends the shelf life of food and protects items against breakage.

“The wonderful thing about polystyrene is that the material consists of 96% air – making it incredibly lightweight. This has a significant impact on carbon emissions during transportation, but also unfortunately causes it to be easily blown away by wind where it becomes visible litter found on beaches or along roadsides,” Adri says.

Few people are aware that used polystyrene is a valuable resource that is readily recycled in South Africa. The collected polystyrene is put through an Ingot machine that transforms into a material used by recyclers for the manufacture of stationery, hangers, picture frames, cornices and skirtings. It is even mixed with a special cement mixture for use in building and construction.

“Polystyrene recycling has grown year-on-year to more than 4 200 tonnes last year, saving 162 350 000 litres of landfill space thanks to their various recycling projects. This is equivalent to 65 Olympic-sized swimming pools filled with polystyrene that was diverted from landfill, that at the same time helped to create more than 48 000 jobs in the plastics recycling industry,” Adri elaborates

Commenting on this exciting development, say Kaveer Singh of Wildlands and Jarred van Niekerk of Rhino Greenbuilding: “We are very excited to become part of this project that will not only divert a valuable item away from landfill, but also help to create jobs and support a growing industry”.

Business and residents in Port Elizabeth are encouraged to take their clean, white polystyrene to their depot situated 15 Voyle Street in Sydenham, while Wildlands readily accepts white and coloured polystyrene that is dropped off at its Recycling Depot situated in Cato Manor in the SPCA Excess Road.

“Every bit counts, and we are asking residents to please make sure that their material is cleaned and void of any left-over food, bones etc. We are working tirelessly to raise awareness about the value of recycled polystyrene amd ensure that recycling remains at the top of everybody’s environmental agenda. To this end, we hope to establish even more collection and recycling depots in and around Durban and PE in the near future,” she concludes.

For more information about polystyrene recycling, visit www.polystyreneassociation.co.za or call +27 72 820 2506

Alternatively email This email address is being protected from spambots. You need JavaScript enabled to view it. (Port Elizabeth) or This email address is being protected from spambots. You need JavaScript enabled to view it. (Durban)

Rich booty of waste collected at 2017 SA Navy Festival

The Plastics|SA Clean-Up crews were once again in action at this year’s SA Navy Festival that took place at the Simonstown harbour from the 17th to the 19th of March.

According to John Kieser, Plastics|SA’s Sustainability Manager and coordinator of the clean-up crews, each year close to 50 000 people visit this event daily for the chance to see some of the country’s biggest naval ships and exhibitions on display.

“This is a very popular festival that is always very well attended by members of the public. As a result, we find that it also produces the biggest variety of waste,” Kieser says. Large volumes of Expanded Polystyrene (EPS), aluminium cooldrink cans and Low-Density Polyethylene (LDPE) were sent away for recycling, whilst organic waste was sent away for composting to Noordhoek.

“We managed to collect approximately 35 large bags of good quality polystyrene that were discarded in the form of take-away containers, but also protective packaging that was used around the ammunition and valuable items that were on display,” Kieser said. This material was delivered to a Cape Town based recycler who uses the post-consumer polystyrene in lightweight concrete used for building and construction applications.

“Our sincere gratitude goes to the Plastics|SA Sustainability Council for the excellent work they are doing on the ground at these events by working closely with the clean-up crews, but also in manning the exhibition stands where they educate members of the public about the importance of recycling. Through their on-going, consistent and visible efforts, they bolster the recycling efforts of the various material recovery organisations (MROs) and help us to divert tons of valuable material from our country’s landfills,” says Adri Spangenberg, Director of the Polystyrene Packaging Council (PSPC).

The final big sporting and spectator event on the Plastics|SA Clean-Up crew’s agenda for this month is the Old Mutual Two Oceans Marathon that will be taking place on the 15th of April 2017.

15 Tonnes of recycled polystyrene used in construction of new Table Bay Mall

More than 15 tons of recycled, Expanded Polystyrene (EPS) have already gone into the production of 20,000 Greenlite Concrete blocks used in the new Table Bay Mall that is currently being constructed. Expected to open its doors at the end of September this year, this 65 000 m² regional shopping centre is located on a 20 ha site on the corner of the R27 (West Coast Road) and Berkshire Boulevard in the heart of the rapidly growing West Coast area.

Vivid Architects / Group Five Construction contractors are at the helm of the project, and specified Greenlight Concrete blocks for use primarily on the fire escape passages owing to the product’s excellent fire rating.

“With climate change looming and the rising cost of energy, building contractors are looking at sustainable building options. Over the past 18 years, we have been involved in the manufacturing and installing of Alternative Building Technologies. We were looking for a more environmentally friendly way of implementing our insulated building systems, when we started experimenting with recycled polystyrene as the basis for our energy efficient walling systems,” explains Hilton Cowie, Technical Director of Greenlite.

Greenlite’s Insulated Concrete is the culmination of more than 18 years’ of experience and research, the blocks consist of recycled polystyrene which is used as a lightweight aggregate mixed with cement and additives to form insulated, soundproof, fireproof, water-resistant lightweight concrete blocks and screeds that have already been used in various large, commercial projects such as the Trumpet Towers in Johannesburg, the BMW Pavilion and Zeits Museum in the V&A Waterfront, Baywest Mall in Port Elizabeth and the Gautrain Station in Sandton.

“The developers were amazed at how quick and easy it was for them to build the walls using Greenlite blocks. Because these blocks are lightweight, they are easy to move around the site and the engineers saved weight loading onto the suspended concrete slabs,” Cowie says.

These blocks are proving invaluable to the construction industry where clients and contractors are able to reduce their structural concrete and steel requirements due to the lightweight nature of the walls. The highly insulated walls also offer the added benefit of further energy savings to the client over the lifespan of the building. Greenlite Concrete accepts any form of polystyrene for recycling on their premises, and is willing to assist in arranging collection of large quantities of Polystyrene.

"We recycle and use the polystyrene faster than we can get our hands on it. Builders Warehouse are now also exclusive stockists of our various sized Jumbo blocks and screeds, creating an even greater demand for polystyrene that we can use,” Cowie explains.

“We are very excited about the growing popularity and rapid market acceptance of this new building technology. Not only does it have a direct and positive impact on our recycling rates by diverting large volumes of post-consumer polystyrene from our country’s landfills, but it also helps to create more employment opportunities, reduce building costs and increases productivity. We are hoping to improve on our 2016 record of 2 036 tons of polystyrene that were successfully recycled through our Project Build,” concludes Adri Spangenberg, Director of the Polystyrene Packaging Council.

For more information, visit www.polystyrenepackaging.co.za or www.greenliteconcrete.co.za

Polystyrene recycling in SA continues to exceed expectations

Polystyrene recycling in South Africa has continued to grow in 2016, contrary to international reports that labelled this versatile product as “challenging to recycle” and sometimes even as being unrecyclable.

According to Polystyrene Packaging Council Director, Adri Spangenberg, the reprocessing of expanded and high impact polystyrene has increased by 106 % between the period 2013 and 2015 in South Africa owing to the fact that more end-markets were developed and knowledge of the fact that the material can successfully be reused in various different applications, continued to grow.

“We are still awaiting the official recycling figures for 2016, but early indications show that approximately 3 600 tons of recycled polystyrene were added to the traditional recycling figures – making this our best year to date,” Adri says.

“We have managed to prove that polystyrene can successfully be recovered from households and industries by working closely with waste management companies and municipalities. Moreover, our recycling projects are undoubtedly successful and yet another proof that South Africa is a truly unique country. We may be small, but we have our own way of doing things and have an ability to find solutions to problems that the rest of the world might find insurmountable,” she says.

Polystyrene is widely being used by spaza shops, take-away vendors, cafeterias and supermarkets around the country due to the fact that it insulates food and beverages, protects food and contents, is cost-effective, lightweight and convenient. Although it is a single-use plastic item, it gets recycled into items that continue to improve lives and create jobs in a variety of different industries, ranging from building and construction, to picture frames, cornices and home décor, clothing hangers and stationery.

“Last year alone, 2 036 tons of polystyrene were successfully recycled for use in lightweight concrete through our Project Build,” Spangeberg says. Hilton Cowie of Greenlite Concrete (http://greenliteconcrete.co.za) in Cape Town and Hennie Snyman of the Get Connected Group in Gauteng were the two biggest projects the PSPC currently supports, and uses recycled, post-consumer polystyrene for large commercial and residential construction projects around the country.

“We needed to have hammermills installed at both these premises last year in order to assist with the processing of the large volumes of polystyrene that are required for their construction projects. These mills are capable of pelletizing 150 kg of expanded polystyrene per hour in order to keep up with the demand,” she explains.

Another area that has seen impressive growth in the amount of recycled polystyrene it used, was the home décor market. More than 1 377 tons of expanded and high impact polystyrene were recycled last year for use in picture frames, cornices and curtain rods through the PSPC’s Project Dècor.

“Apart from the fact that it helped divert polystyrene from landfill, we are particularly pleased that this is another market where jobs and products were manufactured locally as opposed to relying on cheap imports from the Far East that have a detrimental impact on our own markets,” Spangenberg adds.

Looking ahead at 2017, the PSPC will continue to promote the use and the recycling of polystyrene to South Africans of all walks of life. “The Davos World Economic Forum gathering released their report last week in which they called for strategies to dramatically increase recycling of plastic packaging — from the current 14 % to 70 %.

So, whether you are an avid gardener who gets your plants from seedling trays, a business person getting your morning coffee from the work’s canteen or a miner enjoying your afternoon lunch from the cafeteria, the polystyrene you use should be recycled. Plastic is worth much more than its original purpose when used in infrastructure applications. For this reason, we believe that polystyrene should be re-used and recycled into building projects that will benefit many generations to come. Our polystyrene recycling projects not only touch lives and improve communities, but are also key to reclaiming useful carbons and a valuable resource that would otherwise have been lost. Polystyrene recycling helps to create jobs, opportunities and innovative new products in a true, circular economy model,” Spangenberg concludes.