GROWTH, OPPORTUNITY AND POSSIBILITIES FOR PLASTIC PIPE INDUSTRY

The Southern African Plastic Pipe Manufacturers’ Association - with the support of Rare Plastics, Sun Ace, Sizabantu Piping Systems, NSF International and Pipeflo - has concluded hosting its very successful PIPES XII Conference. This year’s event took place on the 27thand 28thof August at the Altron Conference Centre in Midrand and attracted more than 180 delegates, 11 local and 4 international presenters, 15 exhibitors and 9 sponsors who gathered to learn about best-practice designs and applications, share ideas and discuss the latest innovations in so far as plastic pipe manufacturing and installations are concerned. “This year’s event not only provided a platform for our own experts to present, but also drew international participation from as far afield as Germany, Austria and the Middle East. Delegates who attended represented a wide range of different ages, background and industries to include students and academics, engineers, industry representatives, local government, parastatals, pipe fittings and extrusion equipment manufacturers, raw material suppliers and consultants,” reported Jan Venter, Chief Executive Officer of SAPPMA.

Setting the stage: Good news for SA

Economist and scenario analyst Dr Roelof Botha, delivered an optimistic, witty and honest opening keynote address entitled: “Economic recovery beckons if the NDP is implemented” in which he unpacked the challenges and obstacles to growth, but also the exciting opportunities that await South Africa over the next 12 to 18 months. Whilst poor economic leadership over the last 10 years has left South Africa reeling and resulted in GDP losses of at least R2.5 trillion, R653 billion foregone in tax revenue of cost each South African an average of R48 thousand, Dr Botha said that it was not all doom and gloom. He shared good news of real growth reported in retail sales, mineral sales, short term insurance premiums, household and disposable income. “Every problem we have (in South Africa today) can be solved with the right policies and right skills,” Dr Botha said, highlighting the need for more infrastructure and better governance “We are starting to see various green shoots as the positive effect of President Ramaphosa’s leadership. If this continues we can be confident of the future. We have never been in a better position to grow the economy at significantly higher rates than ever before!”

The role of plastic in pipes

The theme of the 2019 PIPES XII Conference was, “Not all plastics are alike” and presenters were encouraged to present their ideas around this theme. “It is almost impossible to imagine our modern life without use of plastics. This versatile material has become deeply embedded in our everyday lifestyle. Although the use of plastic packaging has come under harsh criticism by environmentalists and the public alike over the past year, it is important to recognise that not all plastic is bad for the environment. It is an extremely useful product that is used with great success in pipelines, appliances, cables, computers etc to reduce manufacturing costs, improve performance and reduce mankind’s impact on the environment,” Venter said during his opening speech.

Bigger markets and growing demand

The other the presentations showed how research and development to improve the polymers and processing equipment are dynamic and ongoing throughout the world. This has resulted in the plastic pipe industry enjoying a dominant footprint in most countries. In South Africa, the market grew by 22 % over the past 7 years in order deliver the infrastructure needed support a growing population. Similarly, the development of new markets and applications were unpacked by the various presenters who focussed on outstanding properties of modern plastic pipes, such as flexibility, toughness, corrosion resistance, the growing demand for large diameter pipelines (with pressure pipe now up to 3m diameter), as well as various other exciting technological advancements and applications.

Feedback from presenters and delegates

Feedback received from the delegates were very positive. “This was my first attendance at a PIPES Conference and I thoroughly enjoyed the wide scope of presentations that were delivered. It was interesting to hear about the experiences from the end-users (engineers and consultants),” said Giel van Jaarsveld of SASOL, while Kudzai Jinjika of Proplastics said “the conference was exciting and informative. The excitement was maintained since the very beginning and the food and services were exquisite. I really wished it could be longer than two days!” “One of the best conferences I have attended, thank you!” said Japie Botha of Pro-Plan Consulting Engineers. International presenter Stefan Schiesser of Borealis said “This was a very open and fair conference with excellent possibilities for discussions in the breaks and at the end of the days,” while local presenter Onno Fortuin said “the interaction between industry, suppliers, engineers and planners are critical for the way forward”.

Looking ahead

“Modern plastic pipe materials can be relied upon to provide cost effective pumping solutions, exceptional health standards and previously unheard of service lives. For this reason, it is of great importance to host an annual industry-specific event where we can sharing the latest technical information about design, manufacture, maintenance, evaluation, testing procedures and standards. In an era where taking shortcuts and cutting corners have become the norm, SAPPMA plays an instrumental role in the development, advancement and maintenance of correct standards and performance of piping systems. Together with our members, we will continue to be the flagbearers for maintaining excellent standards and quality in a very important industry through the commissioning of reliable and knowledgeable consultants, pipe manufacturers and installers,” Venter concluded. For more information visit www.sappma.co.za

-- ENDS --

Note to the Editor:

SAPPMA as launched in 2004 to represent the interests of the well-developed plastic pipe business in South Africa and surrounding countries. The purpose of this voluntary, self-regulating association (registered as a Section 21 Company in terms of the Companies Act of SA) is to create consumer confidence within the plastic pipe industry by promoting the production and use of high quality plastic pipes and pipes systems. Only plastic pipes that are manufactured by SAPPMA members and are able to demonstrate that they meet local and international quality standards, are allowed to display the SAPPMA logo.

Straub Pipe Couplings appoints Mechanical Rotating Solutions as South African distributor

Straub pipe couplings has proven itself the world over to be the best pipe-coupling product on the market available today. Based on the original STRAUB coupling technology, which has been demonstrated in more than 40 million pipe connections worldwide, Straub Couplings are the easiest way to join pipes of all materials.

Straub couplings require no special tools or pipe-end preparation and utilising its innovative progressive sealing effect it ensures that when the pressure in the pipe rises, the contact pressure on the sealing lips increases due to the flow through the pressure equalisation channel.

Furthermore, its progressive anchoring effect ensures that when the axial tensile load on the pipe rises, due to increased internal pressure or external influence, the teeth continuously penetrate deeper into the surface of the pipe to compensate.

As a South African agent of Straub products, Mechanical Rotating Solutions is able to procure, install and commission the right Straub connection, which will meet the project-specific requirements fully. Straub Couplings come fully assembled and ready to install.

A torque wrench is the only tool required to do the job. Lightweight and with a low profile, Straub couplings are easy to handle and can be installed in the tightest of spaces. The unique lip seal design seals on even rough pipe surfaces. STRAUB couplings are used to join virtually any plain end pipe or tube including steel, stainless steel, ductile iron, FRP, PVC, CPVC, C900, concrete pipe, copper and CuNi piping.

The removal of a suction pipe for pump maintenance or repair usually requires that either the flange bolts are manually removed, which is highly time consuming, or are removed utilizing a cutting torch which entails acquiring the necessary permits to conduct welding, flame cutting, soldering and similar operations in a plant. Utilising Straub couplings such as the Straub Open Flex cuts pipe disassembly down to 15 minutes!

Whether for water management, renewable energy sectors, industry, shipbuilding and offshore: the STRAUB product range offered by Mechanical Rotating Solutions, stands for sophisticated coupling solutions for pipe systems made from all materials. Mechanical Rotating Solutions offers the complete range of Straub pipe couplings enabling pipe connections for practically all conceivable pipe diameters, for the same or different types of pipe materials, various media and temperatures as well as for a wide range of the operating pressure values.

Straub Couplings are proudly supplied by Mechanical Rotating Solutions, a supplier of world class Mechanical Seals, Rotating and Engineering Protection, Sealing Equipment, and an accredited agent for AESSEAL® MRS is accreddited to ISO 9001:2000, and ISO 14001:2004 quality and environmental standards as well as the OHSAS 18001:1999 Occupational Health and Safety standards. MRS have the full support of AESSEAL® Engineering, Draughting and Quality Services.

Among its product offering and related turnkey solutions, the company is currently servicing the Mpumalanga area with the AESSEAL® product range of mechanical seals and systems, Labtecta Bearing Isolators, Belzona Engineered Coatings and Superbolts, as well as supplying the whole of South Africa with innovative Straub pipe couplings, KSB pumps and valves, and the full HCP range of pumps.

PLASTIC PIPES BODY PLAYS IMPORTANT ROLE IN TRENCHLESS TECHNOLOGY

The development of trenchless technology to rehabilitate existing underground infrastructure with minimal disruption to surface traffic, business, and other activities has left a lasting impact on the construction and civil engineering industries. As the name denotes, trenchless technology requires few or no trenches to be dug in order for the maintenance work to be done and can be defined as "a family of methods, materials, and equipment capable of being used for the installation of new or replacement or rehabilitation of existing underground infrastructure”.

Because trenchless technology greatly reduces the need for invasive excavations, it has a much smaller impact on the surrounding environment, both ecologically and socially. Residential neighbourhoods remain unscathed, commercial districts don’t have to deal with loss of business and rural regions remain undisturbed. Noise and air pollution are also kept to a minimum and rehabilitation time is short.

“In the past, problems caused by aged and damaged sewer and stormwater lines meant digging up and repairing or replacing each section of pipe that needed attention. Completing repairs this way is labour-intensive and costly, not to mention destruction to the surrounding landscape. Now, thanks to modern pipeline trenchless rehabilitation technologies like HDPE pipe lining repair and pipe bursting, we have a cost-effective and more sustainable way to go about repairing pipelines,” says Jan Venter, Chief Executive Officer of the Southern African Plastic Pipe Manufacturers Association (SAPPMA).

As the use of trenchless technology continues to grow popularity and use, so too does the importance of using top quality pipe material that meet the specific requirements of the particular technique being used. For this reason, a sound working relationship exists between the Southern African Association of Trenchless Technology (SASTT) and SAPPMA, whereby the one association focuses on the installation techniques and the latter on the quality and type of materials used.

“The plastics pipe industry is a strategic industry, where hardware needs to be reliable for extended periods of time. According to industry standards, quality plastic pipe should endure in excess of 100 years without failure. For this reason, SAPPMA’s vision is to ensure long term product quality of the materials used – whether it is in standard pipe installations or trenchless technology applications,” Venter explains.

When it comes to trenchless technology, there are many different methods to choose from. However, the two most commonly used applications are:

Pipe Lining: This involves pulling or inverting a new liner into an existing pipe, then applying heat and/or pressure to force the liner to expand and fill the pipe.

Pipe Bursting: This involves fracturing a pipe from the inside and forcing the fragments outwards while a new pipe is drawn in to replace the old pipe

Most of the services that currently provide trenchless techniques, are for reticulation and collector systems of up to 450 mm in diameter. These installations involve the pulling, pushing or expanding of pipes or pipe components into place. Deteriorated pipelines are rehabilitated using various types of slip lining and directional drilling, while existing pipelines can be upsized using pipe bursting and its derivatives.

Thanks to the many benefits it presents in terms of cost-effectiveness, minimised environmental impact and safer procedures, using HDPE pipes in trenchless technology is rapidly becoming the preferred method of rehabilitating pipelines in the construction and civil engineering space. Not only do these pipes offer a 100-year design life, but they also offer solutions to major industry challenges such as corrosion and high leakage rates.

“HDPE pipes are ideal for pulling through long, underground holes as they are flexible, robust and resistant to almost all aggressive elements. These plastic pipes offer a new generation of leak proof, maintenance free and energy efficient pipeline systems that are chemical and abrasion resistant and therefore excellent for use in the lining and relining of pipelines, slurry applications, water reticulation, sewer and storm water systems, the mining industry and in Dolomite areas,” Venter explains.

Another prominent feature of HDPE pipe is the fact that it is available in a wide variety of jointing systems to suit almost any application and installation method, both new and existing. These pipes as can be welded into long continuous lengths before being pulled into place and are available in diameters ranging from 16mm up to 1000mm, and in pressure ranges from PN2.5 to PN25 in PE100. “In order to ensure that the plastic pipes used in trenchless technology applications are manufactured according to international quality standards, SAPPMA has adopted the International Standards Organisation’s (ISO) standards for setting the quality of thermoplastic (in particular HDPE and PVC) pipes, which have been published as SANS/ISO standards. When we audit our member companies, we ensure that their pipes meet these specified, stringent quality standards before they are allowed to carry the SAPPMA mark of approval, in addition to that of a product certification body such as South African Technical Auditing Services (SATAS) or the SABS”.

“We believe that by ensuring that contractors are supplied with piping that meets the high quality standards required for trenchless installations, SAPPMA is playing an important role in supporting the country’s trenchless industry,” Venter concludes.

For more information, visit www.sappma.co.za

Sources:Alaster Goyns – Pipes CC – Email address: This email address is being protected from spambots. You need JavaScript enabled to view it.; http://marleypipesystems.co.za;

https://media.ngage.co.zahttps://en.wikipedia.org/wiki/Trenchless_technology

Closure of Bambanani Pipes and Fittings (PTY) LTD

Press Release: 16 October 2017

After 19-years of operation, Macdonald Holdings has announced that it will be closing Bambanani Pipes and Fittings, its pipe manufacturing and coating division.

The decision comes after 24 months of irregular project work and sustained losses which have been unavoidable in the current market, despite every effort made to revitalise the business. General Manager, Mr. Chris o’ Neill says, “Unfortunately the business has relied on the public sector’s manufacturing and maintenance spend and as this has begun shrinking so has the ability to keep the doors open and profitable. It is never an easy decision when people’s livelihoods are at stake, which is why we have taken every step possible, despite two years of losses, to look at positive solutions for the business. Sadly though, none of these has resulted in a marked turnaround and as such the shareholders have decided to call an end to the business.”

Bambanani was formed in 1998 by a management buy-out of the ex-Hall Longmore operation that was based in Luipaardsvlei, Krugersdorp. In 2008 Bambanani became a member of the Macdonald Group of Companies and is a 100% BEE owned company with a level 1 BBBEE scorecard. It seems though, that despite these positives including a massive investment in a new facility and the very real consensus from clients of a brilliant product, that another once successful business is taking the brunt of a market downturn.

-- Ends --

About Bambanani Pipes and Fittings:

Bambanani Pipes and Fitting is currently located on a 40 000m2 facility in Roodepoort. The company provides manufacturing, coating and lining facilities, offering products in carbon and stainless steel for the use in various market sectors such as water reticulation petrochemical, power, paper, pulp, mining, construction, telecommunication, sewerage works and general industrial projects.

Website: www.bampipe.co.za

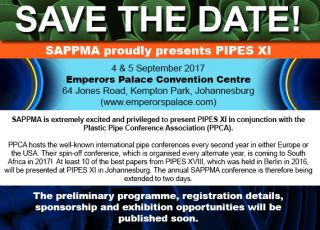

SAPPMA AND PPCA’S PIPES XI CONFERENCE: BIGGER AND BETTER THAN EVER BEFORE!

More than 35 of South Africa and the world’s top experts on issues relating to plastic piping, water infrastructure and engineering will be presenting at this year’s PIPES XI Conference – an annual event hosted by the Southern African Plastic Pipe Manufacturers Association (SAPPMA).

This year’s event will be unlike any other event the association has ever hosted and promises to be an unforgettable experience.

“We are extremely privileged to be hosting our conference this year in conjunction with the Plastic Pipe Conference Association (PPCA). It will be a two-day event taking place on the 4th and 5th of September 2017 at Emperor’s Palace Convention Centre, conveniently located close to the OR Tambo Airport in Gauteng. In addition to the line-up of top national and international speakers we would normally have at our conference, this year’s PIPES XI also see at least 10 of the best papers which were presented at PIPES XVIII in Berlin last year, delivered to our local audience,” says Jan Venter, CEO of SAPPMA.

Every two years, the PPCA plays host to the world’s biggest international pipe conference which takes place either in Europe or the USA. Venter explains that it is the first time in history that their spin-off conference, which is organised every alternate year, will be coming to South Africa.

"The excitement over the event is tremendous. We have already sold an impressive amount of tickets and are hoping to have more than 300 delegates attending both days,” Venter says.

As an added incentive, SAPPMA is offering an early bird booking discount of 10 % for all bookings and payments made online (www.pipesxiconference.co.za) before the 31st of May 2017.Topics that will be covered at this year’s event are varied, ranging from raw materials and additives to the life cycle and material design of plastic pipes. Installations, applications and rehabilitations as well as standards, testing and certification, and various case studies will also be addressed.

The opening keynote address will be delivered by Dr Roelof Botha, a local economist of the GOPA Group, after which various delegate can select to listen to presentations in two break-away sessions. International speakers who will be presenting on Day 1 (Monday, 4 September) include Zoran Davidovski of Pipelife International (presenting on behalf of TEPPFA in Austria) on “Main barriers to plastic pipes”, Tony Radoszewski of PPI in the USA, on “Manufacturing and Infrastructure in the Age of Trump”, Bruce Hollands of the PVC Pipe Association in the USA on “Life Cycle assessment of PVC Water and Sewer pipe and comparative sustainability analysis of pipe materials and Jean-Pierre De Grève of PVC4Pipes in Belgium on “Evolution and benefits of PVC pipes”, to name but a few.

The day’s activities will end with cocktail function and entertainment, before the Day 2 (Tuesday, 5 September 2017), will see more local and international speakers, including Dane Tallen of Baerlocher in Germany, Dr Predrag Micic of Qenos, Australia, Rob Spekreÿse of Rollepaal in the Netherlands and Robin Bresser representing Borealis in Austria take to the stage. Final closing remarks will be made by Zoran Davidovski.

“We cannot emphasise enough the importance of this event, and encourage local engineers, students, specifiers and decision makers on all levels to make the most of this opportunity to be exposed to this kind of professionalism and expertise. We would never be able to host such a big event without the support of our industry and would like to particularly thank the sponsors (Macneil Plastics, Sun Ace, Rollepaal, Van Ryn Rubber, Hultec, AENOR-CEIS, Baerlocher, Marley Pipe Systems, Zerma Africa, Molecor/Sizabanthu Piping Systems, DPI Plastics, PipeFlo, Plastiweld and Plastics|SA) who are making it possible for us to host this event and keep the delegate fees as low as possible.

* SAPPMA and IFPA members: R2 600 pp (excluding VAT)

* Non-members: R3 500 pp (excluding VAT)

* Group bookings (5 delegates or more): R1 900 pp

For more information about the speakers, programme of events or to register, visit www.pipesxiconference.co.za or email This email address is being protected from spambots. You need JavaScript enabled to view it. / This email address is being protected from spambots. You need JavaScript enabled to view it.

PPCA confirms spin-off Conference and Exhibition to take place in South Africa later this Year

The Plastic Pipes Conference Association (PPCA) has announced dates and venue for its two spin-off conferences and exhibitions in South Africa and China for this year. The first event in South Africa will be held on 4 -5 September 2017 at the Emperors Palace in Johannesburg. The second will be hosted in Hangzhou, China on 26-27 October 2017.

The PPCA is organizing these events in close collaboration with the respective plastic pipe associations, namely the Southern African Plastic Pipe Manufacturers Association (SAPPMA) and the China Plastics Piping Association (CPPA). In South Africa, the conference will be held in conjunction with PIPES XI, the annual plastic pipes event organized by SAPPMA. At least ten papers will be included from the international Plastic Pipes Conference held in Berlin during 2016. For this reason, the duration of PIPES XI has been extended to two days.

Zoran Davidovski, spokesman for the events forecasts large attendances. “Our industry is in a constant process of innovative change as it finds new solutions for replacing aging steel and concrete pipe systems. In the midst of these improvements, industry and government are faced with the need for new technical standards.”

“Our conferences will showcase new developments and enable stakeholders to consider the international work that has been carried out in the field of standards, sustainability and experience. This will be particularly interesting for the South Africa and China markets.”

The Baerlocher Group is one of the major sponsors of both regional conferences. Molecor and Rollepaal have also confirmed their sponsorship participation at the Johannesburg event.

For South Africa, full details of program, registration, exhibition and sponsorship opportunities will be posted shortly on their website: www.sappma.co.za

The CPPA will similarly publish the relevant information on: http://www.ppia-china.com/en/aboutme.asp?types=SQ

Further Information: This email address is being protected from spambots. You need JavaScript enabled to view it.

Note to editors: Member associations of the PPCA are the PE 100+ Association, Plastics Pipe Institute, PVC4Pipes and The European Plastic Pipe and Fittings Association (TEPPFA). PPCA conferences and exhibitions are self-financing and any profits re-invested in future conferences, educational tools or “spin-off” events