GROWTH, OPPORTUNITY AND POSSIBILITIES FOR PLASTIC PIPE INDUSTRY

The Southern African Plastic Pipe Manufacturers’ Association - with the support of Rare Plastics, Sun Ace, Sizabantu Piping Systems, NSF International and Pipeflo - has concluded hosting its very successful PIPES XII Conference. This year’s event took place on the 27thand 28thof August at the Altron Conference Centre in Midrand and attracted more than 180 delegates, 11 local and 4 international presenters, 15 exhibitors and 9 sponsors who gathered to learn about best-practice designs and applications, share ideas and discuss the latest innovations in so far as plastic pipe manufacturing and installations are concerned. “This year’s event not only provided a platform for our own experts to present, but also drew international participation from as far afield as Germany, Austria and the Middle East. Delegates who attended represented a wide range of different ages, background and industries to include students and academics, engineers, industry representatives, local government, parastatals, pipe fittings and extrusion equipment manufacturers, raw material suppliers and consultants,” reported Jan Venter, Chief Executive Officer of SAPPMA.

Setting the stage: Good news for SA

Economist and scenario analyst Dr Roelof Botha, delivered an optimistic, witty and honest opening keynote address entitled: “Economic recovery beckons if the NDP is implemented” in which he unpacked the challenges and obstacles to growth, but also the exciting opportunities that await South Africa over the next 12 to 18 months. Whilst poor economic leadership over the last 10 years has left South Africa reeling and resulted in GDP losses of at least R2.5 trillion, R653 billion foregone in tax revenue of cost each South African an average of R48 thousand, Dr Botha said that it was not all doom and gloom. He shared good news of real growth reported in retail sales, mineral sales, short term insurance premiums, household and disposable income. “Every problem we have (in South Africa today) can be solved with the right policies and right skills,” Dr Botha said, highlighting the need for more infrastructure and better governance “We are starting to see various green shoots as the positive effect of President Ramaphosa’s leadership. If this continues we can be confident of the future. We have never been in a better position to grow the economy at significantly higher rates than ever before!”

The role of plastic in pipes

The theme of the 2019 PIPES XII Conference was, “Not all plastics are alike” and presenters were encouraged to present their ideas around this theme. “It is almost impossible to imagine our modern life without use of plastics. This versatile material has become deeply embedded in our everyday lifestyle. Although the use of plastic packaging has come under harsh criticism by environmentalists and the public alike over the past year, it is important to recognise that not all plastic is bad for the environment. It is an extremely useful product that is used with great success in pipelines, appliances, cables, computers etc to reduce manufacturing costs, improve performance and reduce mankind’s impact on the environment,” Venter said during his opening speech.

Bigger markets and growing demand

The other the presentations showed how research and development to improve the polymers and processing equipment are dynamic and ongoing throughout the world. This has resulted in the plastic pipe industry enjoying a dominant footprint in most countries. In South Africa, the market grew by 22 % over the past 7 years in order deliver the infrastructure needed support a growing population. Similarly, the development of new markets and applications were unpacked by the various presenters who focussed on outstanding properties of modern plastic pipes, such as flexibility, toughness, corrosion resistance, the growing demand for large diameter pipelines (with pressure pipe now up to 3m diameter), as well as various other exciting technological advancements and applications.

Feedback from presenters and delegates

Feedback received from the delegates were very positive. “This was my first attendance at a PIPES Conference and I thoroughly enjoyed the wide scope of presentations that were delivered. It was interesting to hear about the experiences from the end-users (engineers and consultants),” said Giel van Jaarsveld of SASOL, while Kudzai Jinjika of Proplastics said “the conference was exciting and informative. The excitement was maintained since the very beginning and the food and services were exquisite. I really wished it could be longer than two days!” “One of the best conferences I have attended, thank you!” said Japie Botha of Pro-Plan Consulting Engineers. International presenter Stefan Schiesser of Borealis said “This was a very open and fair conference with excellent possibilities for discussions in the breaks and at the end of the days,” while local presenter Onno Fortuin said “the interaction between industry, suppliers, engineers and planners are critical for the way forward”.

Looking ahead

“Modern plastic pipe materials can be relied upon to provide cost effective pumping solutions, exceptional health standards and previously unheard of service lives. For this reason, it is of great importance to host an annual industry-specific event where we can sharing the latest technical information about design, manufacture, maintenance, evaluation, testing procedures and standards. In an era where taking shortcuts and cutting corners have become the norm, SAPPMA plays an instrumental role in the development, advancement and maintenance of correct standards and performance of piping systems. Together with our members, we will continue to be the flagbearers for maintaining excellent standards and quality in a very important industry through the commissioning of reliable and knowledgeable consultants, pipe manufacturers and installers,” Venter concluded. For more information visit www.sappma.co.za

-- ENDS --

Note to the Editor:

SAPPMA as launched in 2004 to represent the interests of the well-developed plastic pipe business in South Africa and surrounding countries. The purpose of this voluntary, self-regulating association (registered as a Section 21 Company in terms of the Companies Act of SA) is to create consumer confidence within the plastic pipe industry by promoting the production and use of high quality plastic pipes and pipes systems. Only plastic pipes that are manufactured by SAPPMA members and are able to demonstrate that they meet local and international quality standards, are allowed to display the SAPPMA logo.

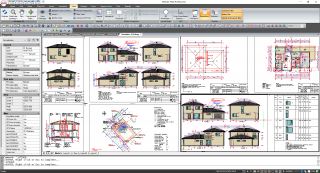

Only 10 in the country made it to the finals, CAD4ALL is one of them!

The PG Bison 1.618 Education Initiative 2019 has just revealed the top ten finalists in South Africa in their coveted design competition.PG Bison is a highly soughtafter event, garnering hundreds of entries from design and architecture institutions from across the country confirming the popularity thereof.

Pretty sure the judging panel had a tough time deciding on the shortlist. Following on the yearly success of the PG Bison campaign and its 23 years of existence, this is only Cad4all Design College second year of participation in competing in this acclaimed event.Cad4all Design has only received full accreditation for our design qualifications in 2014,thus making us adolescent in industry in comparison with our established competitors which proves that it is not about the length of existence but the depth of our passion.

We have yet proven that we have the tenacity and competency to compete with the very best in industry .Cad4all is immensely honoured to receive this massive recognition and commends the extensive work put in over the weeks by its dedicated staff and our very own Jano Fourie who was selected as a top 10 finalist in SA. His work was judged collectively in an anonymous process by a panel of leading industry experts.

Cad4all Design College has experienced some tough battles and trying ordeals over the weeks but remained composed and inspired to prove the contrary against daunting odds. The most memorable achievements, such as this selection of one our students as a top ten finalist, are the ones to be treasured as no one predicts or expects its occurrence.

Cad4all Design College is committed to higher learning and endears itself to the learners enrolled for a caliber of education paralleled to excellence. Jano Fourie, we are super delighted of this memorable achievement and CAD4ALL wishes to express our full support to you in your journey to success. We wish you the very best in the race to the end of the PG Bison 2019 competition and know that you have put in so much to inspire us all.

CAD4ALL College is overjoyed with the hardworking class of 2019 and the dedication and commitment of its diligent staff.In the words of Amelia Barr,” It is always the simple that produces the marvelous.” Visit the home of AEC education on www.cad4all.co.za

The CAD4ALL EGD Academy linking our graduates to our corporate clients

The CAD4ALL EGD Academy linking our graduates to our corporate clients CAD4ALL is the leading provider of CAD design education and a significant provider of employees to industry. Cad4all Career and Design College is one of Cape Town’s first private accredited design institution within the AEC industry. Offering a unique, professional environment in lectures taught by working professionals who are experts in their specific fields.

The CAD4ALL curriculum offers subject matter experts in specialist areas bringing extensive industry experience thus providing an opportunity to bring your creative passion to life.With more accredited qualifications offered in 2020, CAD4ALL pioneered and set up the first EGD Academy for all Grade 12 learners creating a hub for them to access resources, information and design software within the AEC industry. CAD4ALL College focuses on teaching in single discipline specific areas only.

Organisations that offer a wide array of qualifications from IT to Business, and design only as an abstraction from their product offering usually achieve generic competencies for their learners because of the lack of technical specialization.

CAD4ALL is the leading provider of design education and a significant provider of potential employees to industry for thee past 11 years Through the CAD4ALL corporate database and as a single point of contact the learners from our academic institution may now seamlessly connect to a variety of business opportunities for possible employment.

CAD4ALL offers expertise in which AEC companies can access the talent pool of graduates at no cost. Come and join a 11-year CAD4ALL AEC history where you gain design experience professionally from the ground up.

Work directly with qualified lecturers and career advisors to collaborate a design portfolio to develop employment goals and a path to get there.

CAD4ALL the home of AEC Education designed for you in the AEC industry, Study at CAD4ALL both inContact and online at the most competitive tuition fees in Cape town.Get social and visit us on our Open Day on the 31 August 2019 and register on our website www.cad4all.co.za

4M CAD Promotion

4M provides the Architecture, Engineering & Construction community with advanced CAD & BIM Software since 1986. Intelligent Building Design has never been so easy and affordable.

4M provides the Architecture & Engineering Community with Advanced Verticals and with Innovative BIM Solutions. Today 4M has more than 35.000 Active Users in over 40 Countries Worldwide

Powered by the technology, all the 4M Software offer an unrivalled compatibility with AutoCAD ® by using DWG as their native file format.4M has a user base of over 35.000 users closely supported by a network of highly professional partners in more than 40 countries.

CAD4ALL has been the sole distributor for 4M in Southern Africa for the past 8 years expanding the 4M Footprint sustainably over the past few years. CAD4ALL offers expert CAD service as well as accredited training in CAD and Various courses and Qualifications.

Cad4all Corporate Solutions (CCS)established in Cape Town is a proud division of Cad4all Career and Design College. CCS was founded as a consulting company that specializes in partnering with corporates to provide insight and direction to guide B-BEEE implementation.

Our Corporate Strategic Training and Consulting solutions division with industry experts enables us to create the best strategic transformation plan that will help corporates to maximise the most out of their B-BEEE. In any business in South Africa a BEE scorecard is an important element hence encouraging business owners to understand the scoring and value thereof.

The higher your BEE score the better chances of your business gaining opportunities with favourable tax gains

Two SA Entrepreneurs Selected for Africa Prize for Engineering Innovation

The Cape Innovation and Technology Initiative and the Royal Academy of Engineering once again work together on the Africa Prize for Engineering Innovation 2018. Two South African companies are amongst the final 16 shortlisted candidates.

Monday 3 December 2018, Cape Town – Pelebox Smart Lockers and the Hybrid Five-Axis Machine Tool are the two South African innovations that are on the shortlist for the Royal Academy for Engineering’s Africa Prize for Engineering Innovation, accelerated by the Cape Innovation and Technology Initiative (CiTi).

CiTi is Africa’s oldest tech incubator, in its 20th year in 2019, and the Royal Academy of Engineering is the United Kingdom’s prestigious national academy for engineering and technology since 1976. Since 2017, the Royal Academy of Engineering has worked with CiTi to support engineering and tech entrepreneurs from across the continent in developing their unique scalable solutions to local challenges. After a highly successful first cohort together, the Royal Academy of Engineering once again selected CiTi as the primary programme incubation partner to support the 16 businesses from the following 6 African countries in 2018/19: Nigeria, Zambia, Kenya, Uganda, Burkina Faso and South Africa.

The programme, designed by CiTi specifically for the Royal Academy of Engineering, uses a remote incubation model, delivering entrepreneurial training, coaching and mentorship over the 7-month programme period; coupled with three residency weeks which include workshops, networking events and local entrepreneurial engagement sessions. The first residency week took place in Cape Town at the Bandwidth Barn in early November, and the following two will take place in London and Kampala. The entrepreneurs also stand a chance to receive £25,000 (R450,000) at the end of the programme, and all will have direct access to both the Academy and CiTi’s vast network of engineers, tech professionals, businesses and industry leaders.

“We have found a dynamic synergy with the Royal Academy of Engineering, especially around our shared impact values,” states Ian Merrington, CEO of the Cape Innovation and Technology Initiative (CiTi), “Making a difference and improving lives through technology by accelerating African innovation and African entrepreneurs is an objective shared by both organisations. CiTi has relished the opportunity to design a pan-African incubation programme. We now find ourselves strongly positioned as an African partner to international organisations who want to deliver high-impact support for entrepreneurship on the continent through hybrid models of training and mentorship.”

On why the Royal Academy of Engineering selected Cape Town-based CiTi as its incubation partner, Meredith Ettridge, Senior Manager for International Development at RAE, states: “Earlier this year we undertook a competitive tender process with a number of strong applications, following careful review we were very pleased to appoint CiTi as the training provider for the 2019 Africa Prize for Engineering Innovation, building on the success of the previous year. We were particularly pleased to award the contract to a training provider based in sub-Saharan Africa, and with such a strong history of support for entrepreneurs nationally and regionally.”

With Cape Town recently being named the leading Tech Hub of Africa, it should come as no surprise that two of the companies hail from SA.

“CiTi has a strong network of trainers and mentors in Cape Town so it was an easy decision to hold the first training session here. Cape Town also has a thriving technology ecosystem which was evident during the myriad of events happening as part of Global Entrepreneurship Week which allowed our shortlist to make excellent new connections,” adds Meredith Ettridge.

The Hybrid Five-Axis Machine Tool is the first of the South African innovations on the shortlist, developed by Dr Lukas du Plessis. Du Plessis’s hybrid machine tool works on five axes to allow users to shape, cut, grind, shear and otherwise form metals and hard materials with more precision.

“There’s so much manufacturing in South Africa that could be greatly improved if small and medium-sized businesses could afford machining tools like this – and my hope is to change that,” states Dr Lukas du Plessis, founder of the Hybrid Five-Axis Machine Tool.

He continues: “What I hope to gain from this experience is twofold: (i) A fundamental understanding of entrepreneurial business so that I can support entrepreneurs in South Africa to establish compact manufacturing firms that are competitive internationally. (ii) I also hope to find a partner who shares my manufacturing vision and passion for machine tools.”

The second South African innovation is the Pelebox Smart Locker system developed by Neo Hutiri.

Pelebox is a smart locker system designed for public healthcare facilities to dispense chronic medicine to regular patients, cutting down on long queues and easing pressure on clinic resources.

Developed by Hutiri and his team for the South African healthcare system, the Pelebox is a simple wall of lockers, controlled by a digital system in the centre. Healthcare workers stock the lockers with chronic prescription refills, log the medicine on the system, and secure each locker. Pelebox then sends patients a one-time PIN, which they simply enter into the system to unlock their medicine.

“The public healthcare system is so often under strain, and Pelebox can take a lot of pressure off clinics who fill repeat prescriptions for regular patients,” comments Neo Hutiri, founder of Pelebox Smart Lockers.

He adds: “To be considered amongst thousands of innovators and entrepreneurs that would have applied for this prize is a testament to the work that we are doing on the ground in leveraging technology to serve people. Our vision is to create and promote inclusive technologies solving challenging issues in health. We feel that we are well positioned to solve the issue of long queues in clinics through technology that is patient-centric and easy to use.”

Hoxana Consulting Engineers changing lives for the better living conditions for Wesselton residents

The growing number of informal settlements in South Africa is increasing pressure on basic services that the government has to provide such as water and sanitation, housing and electricity, challenges both local and national government are working extremely hard to address. Hoxana Consulting Engineers has partnered with various local municipalities to deliver service of the highest quality as part of government’s commitment to eradicate dire conditions in disadvantaged communities such as Wesselton, Ermelo.

The Wesselton settlement consists of both formal and informal settlements which have developed as a result of the housing shortages in the area. Wesselton Extension 5 currently has 100 informal structures housing 400 people, and extension 10 has a total of 51 informal living structures which are home to 212 residents.“These informal settlements are a health hazard and a resolution to formalize all informal settlements has been made by Msukaligwa Local Municipality (MLM)”, says Livingstone Mashele, Managing Director at Hoxana Consulting Engineers.

The Msukaligwa Local Municipality appointed Hoxana Consulting Engineers to undertake the planning, design and construction monitoring for the implementation of the extension of sewer reticulation from Wesselton Extension 5 and 10. The estimated cost of the proposed sewer reticulation and toilets for Wesselton Ext 5 is valued at R 2 390 429.98 and R 1 703 250.52 for Wesselton Ext 10.The completion of the sewer reticulation will greatly improve the quality of life for all residents through hygienic living conditions, reduction in pollution and eradication of water borne diseases such as Cholera and Typhoid.

Hoxana Consulting Engineers will also ensure that local communities benefit from the project through the adoption of labour intensive construction methods and training. “At Hoxana, we strongly believe in community upliftment which is why approximately 60% of this project will be executed through labour Intensive process in order to empower the local labourers and to provide technical skills to the local community”, says Mashele.The Wesselton project began 29 January 2018 and should be completed and handed over to the local community on at the end of June 2018.

Pipes XI Conference sets the Bar High for Local Plastic Pipe Industry

SAPPMA’s (Southern African Plastic Pipe Manufacturers Association) PIPES XI Conference that took place at Emperors Palace in Gauteng this past week (4-5 September 2017) has set the bar high for the future of South Africa’s water infrastructure and engineering professionals.

More than 300 delegates from around South Africa were treated to two days of in-depth and world-class presentations delivered by 18 international and 17 local experts on issues relating to plastic piping, water infrastructure and engineering courtesy of the Plastic Pipe Conference Association (PPCA) who sponsored the best speakers of the recent PIPES XVIII conference in Berlin last year, to present in South Africa in a spin-off conference.

According to the PPCA’s Zoran Davidovski, they have had six spin-off conferences around the world since the first one was hosted in Beijing in 2009. “Just as connections are vital in the pipe industry, so too are the connections made between people and professionals in this field, and for this reason we are pleased to see the South African industry so well represented as this year’s conference,” he said, stressing the importance of attending and hosting international conferences.

“Survival needs invention, and the best way to be inspired and to learn is by allowing yourself to be educated and your mind stretched by learning from your local and international peers”.

Highlights of the conference included a keynote address by guest speaker and well-known economist, Dr Roelof Botha, who looked into his proverbial crystal ball to predict whether or not the state capture will force the South African economy into a recession. Botha offered a closer look at the socio-political landscape of the country and how this would impact the local economy and the plastic pipe industry specifically.

“The next 18 months will be turbulent, but this doesn’t mean there won’t be opportunities for growth. What we are currently experiencing in our country is a deepening of a democracy. It is important for us to invest in skills transfer, public-private partnerships and to restore the functionality of our leadership. With effective leadership, smart policies and team work, there can still be a bright future for South Africa,” Botha encouraged.

Other speakers who presented include Tony Radoszewski (PPI in the USA) who presented on “Manufacturing and Infrastructure in the Age of Trump”, Bruce Hollands (PVC Pipe Association in the USA) on “Life cycle assessment of PVC water and sewer pipe and a comparative sustainability analysis of pipe materials”, and Dr Andreas Frank (Polymer Competence Centre in Austria) on “Lifetime prediction of PE100 pipes based on slow crack growth resistance,” to name but a few.

When asked what they thought of this year’s PIPES XI conference and whether or not it had benefitted them to attend, the delegates were very outspoken and full of praise for the level of expertise of the presenters.

“This was a high quality conference with excellent networking opportunities,” said Charl Fourie, Technical Manager at Chemsystems.

“It was a great platform for learning and interacting with my South African and international peers. I was very impressed,” said Neo Mekgoe, Marketing Assistant at Safripol.

“I will definitely attend SAPPMA’s PIPES conferences in future. I highly recommend it to anyone! I really enjoyed the last two days and learned a lot,” said Werner van Huysteen, Sales Manager at Alprene Plastic Products.

“It was amazing to have these world leaders who are considered to be the guru’s in the field on South African turf and presenting to us. Attending their presentations at international conferences is almost an economic impossibility for South Africans, but having these calibre of speakers here and at such an affordable rate was an opportunity that nobody should have missed,” said George Dilliyannis, Technical Support Engineer at Safripol.

SAPPMA CEO Jan Venter said the PIPES XI conference once again highlighted the importance of pipes and pipelines in civilization and infrastructure. “Water distribution, waste disposal, irrigation and telecommunications all rely on pipelines to function. An extensive network of reliable water and sewage pipelines are essential for establishment and growth of civilization. Although we find ourselves operating in a tough business climate and the economic recovery has not been what we hoped it would be, the importance of what we are do remains undiminished. We take a long term view on these things, and will continue to fight for maintaining the standards and integrity of the plastic pipes being manufactured and installed locally,” Venter said.

Davidovski concluded the conference by saying that it is clear that South Africa faces many challenges and resistance to change. However, technology it is encouraging to see that despite this, the technology employed in the manufacturing of plastic pipes is increasing both the quality and the quantity of drinking water to the country and its people.

“Much of the presentations delivered at this conference centred around sustainability and invention. It is important to remember that these are never cast in concrete... We look forward to seeing what will come out of SAPPMA’s PIPES XII Conference next year, and will continue to keep a watchful and expectant eye on the South African plastic pipe industry which has proved itself to be tenacious, committed to excellence and passionate about raising standards,” Davidovski said.

For more information about this year’s PIPES XI conference, visit www.pipesxiconference.co.za or www.sappma.co.za

RS Components announces availability of pre-terminated cable assemblies from Molex

Range of pre-prepared cable assemblies for popular Molex connector families provides cost-effective solution for markets including communications, consumer and industrial

Johannesburg, South Africa, 24 August, 2017 - RS Components (RS), the trading brand of Electrocomponents plc (LSE:ECM), the global distributor for engineers, has announced availability of a number of pre-prepared cable assemblies that provide compatible solutions for key product ranges from Molex, one of the world’s leading manufacturers of connectors and interconnection components.

Targeting a wide range of applications in industries including automotive, consumer, defence, industrial and medical, as well as telecommunications and networking, the new Molex range of pre-terminated cables makes it even easier for engineers to adopt interconnection components in new and existing designs, removing the need for expensive tooling, long production times and laborious testing procedures.

The wire-to-board cable assemblies have been designed with terminations chosen to work with some of Molex's most popular interconnection families. These include the FIT range (Micro-FIT, Mini-FIT Jr. Nano-FIT and Mega-Fit), as well as the CLIK-Mate and Micro-Clasp and Pico-Clasp connector ranges.

The Molex pre-terminated cable assemblies are now available from RS.

-- Ends --

About RS Components

RS Components is the market leader in the high service level distribution of electrical, electronic, mechanical, tools and industrial products. Operating in 26 countries whilst serving a further 100 through third-party distributors, RS serves every sector of industry in the procurement of their products relating to maintenance, repair, operations, low volume production, research and development.

With over 500 000 products across 2500 leading brands, the company is committed to ensuring that their 1,5 million customers have fast access to a broad, as well as deep range, of products and technologies, all under one roof. RS’s customers, whether ordering single or multiple items, experience a quick, easy, secure, painless and cost effective process.

The RS catalogue, available at za.rs-online.com, offers full colour pictures with extensive clear product specifications. Free access to thousands of datasheets ensures the correct product choice.

Order placement is easily facilitated through za.rs-online.com, the call centre, e-mail, fax and trade counter. Locally held stock is delivered to customers within 24 hours, and products held internationally, within four to six working days.

It is proven that departments traditionally spend 80% of their time sourcing products that account for only 20% of their total procurement spend. RS is focussed on reducing the customers “total cost of product ownership” by reducing the need to make multiple calls to various companies to source products, reducing supplier related administration and allowing for the amalgamation as well as consolidation of supplier bases.

Through this process, procurement efficiency is improved and time is freed up to concentrate on the more important business decisions. For more information, please visit the website at za.rs-online.com

Press Office

Le-andra Olivier

PR and Communications Specialist

RS Components South Africa

This email address is being protected from spambots. You need JavaScript enabled to view it.

+27 11 691 9345

Further information is available via these links

- Twitter: @rsonline_SA; @DesignSparkRS

- Facebook: facebook.com/rssouthafrica/

- RS Components on LinkedIn -

- http://www.linkedin.com/company/rscoms

Relevant Links

RSPro

RS Components South Africa

www.electrocomponents.com

DesignSpark Magazine - http://www.designspark.com

CPUT Engineering Labs turn Pro

Johannesburg, South Africa, 23 August 2017 - RS Components the global distributor for engineers recently partnered with the Cape Peninsula University of Technology to kit out their new engineering labs in Bellville, Cape Town. RS Sponsored equipment to the value of R250 000 to be used in the project labs which are run by the Department of Electrical, Electronic and Computer Engineering (DEECE).

The four project labs will be used by over 450 students annually, to learn about electronics, mechanical and electrical engineering. The students will get the opportunity to learn about and work with actual engineering equipment by doing various assignments and projects according to their course curriculum.

The Cape Peninsula University of Technology (CPUT) is the only university of technology in the Western Cape and is the largest higher education institution in the region. The equipment supplied to the labs is from RS’s private label range, called RS Pro – short for ‘professional’.

This range has grown to more than 50 000 high-quality, competitively priced industrial products and electronic components that have been developed over a period of 80 years in conjunction with global manufacturers.“RS Components has always been engaged in developing and supporting engineers and in recent years our involvement with education has grown in line with the demand for young people with STEM skills in South Africa,” said Brian Andrew, GM of RS Components South Africa.

“Being the global distributor for engineers and technical professionals, it made sense to partner with the CPUT as they are developing the next generation of technicians and technologists who are going to be required to be multi-skilled across engineering disciplines. We wanted the students to have access to the necessary tools and equipment so that they could practically put the theory they are studying into practice and have a taste of what the professionals use. Our RS Pro range matched the requirements of the labs by having great quality and performance while being affordable. We are extremely excited to see what these young students will be cooking up in the labs.” The official opening of the labs will take place on the 24th of August at the CPUT Bellville Campus.

There will be an opening by the Dean of the Faculty followed by a tour of the project labs.

About RS Components

RS Components is the market leader in the high service level distribution of electrical, electronic, mechanical, tools and industrial products. Operating in 26 countries whilst serving a further 100 through third-party distributors, RS serves every sector of industry in the procurement of their products relating to maintenance, repair, operations, low volume production, research and development.

With over 500 000 products across 2500 leading brands, the company is committed to ensuring that their 1,5 million customers have fast access to a broad, as well as deep range, of products and technologies, all under one roof. RS’s customers, whether ordering single or multiple items, experience a quick, easy, secure, painless and cost effective process.

The RS catalogue, available at za.rs-online.com, offers full colour pictures with extensive clear product specifications. Free access to thousands of datasheets ensures the correct product choice. Order placement is easily facilitated through za.rs-online.com, the call centre, e-mail, fax and trade counter. Locally held stock is delivered to customers within 24 hours, and products held internationally, within four to six working days.

It is proven that departments traditionally spend 80% of their time sourcing products that account for only 20% of their total procurement spend. RS is focussed on reducing the customers “total cost of product ownership” by reducing the need to make multiple calls to various companies to source products, reducing supplier related administration and allowing for the amalgamation as well as consolidation of supplier bases. Through this process, procurement efficiency is improved and time is freed up to concentrate on the more important business decisions.

For more information, please visit the website at za.rs-online.com

For more information contact

Shaun Watson

Account Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

+27 (0) 87 941 3497

30 Schools do CAD Training for F1 in Schools Competition

Over the July holidays 170 pupils from 30 schools in the Gauteng region, including 30 teachers competed a computer Aided Design (CAD) introduction course in preparation for the 2017/18 F1 in Schools race season.

The training, provided by Sangari Education, was done at Tshwane University of Technology. The teams that attended are competing for the chance to go to the international competition in 2018.

“Students and teachers worked through tutorials, and on completion, each team designed their own F1 cars that will be competing in the racing scheduled to start in August,” said Pieter du Plessis, F1 in Schools programme manager at Sangari Education.

“Based on each team’s design, the F1 cars will be manufactured at Sangari Education’s offices overlooking the Kyalami race track. It is a great setting to prepare for the F1 in Schools competition,” he said.

The racing cars are designed using Siemens’ Solid Edge CAD software supplied locally by ESTEQ, who are also assisting Sangari with training of the teachers. This software is used for designing the shape as well as simulating the airflow allowing the design to be optimised before sending through for manufacture on a high-precision milling machine.

“The vehicles are then tested in a wind tunnel to ascertain the resistance characteristics and modifications are made if necessary.” The world record is 0.997 seconds for the F1 cars rocketing along the 20m race track.

In support of the F1 in schools Challenge the Gauteng Department of Education has deployed Technology Senior Education Specialists in every district to assist with the roll-out of the programme. The Department is excited to see the impact the experience will have on the learner’s ability to relate to the theory being taught in the technology syllabus and the overall improvement in Maths, Science and Technology results, said Mr du Plessis.

F1 in Schools is as an educational competition that promotes Science, Technology, Engineering and Mathematics (STEM) where schools build a model F1 racing car and compete in inter-school racing competitions. The winning team will represent South Africa at the international finals later this year,” said Bez Sangari, CEO of Sangari Education.

Pule Kgasoe, teacher at Aurora Girls High School in Soweto, who competed in the 2016/17 season, said: “The competition has raised our students’ work ethic. They are now more organised and disciplined, and the programme has created new interest in maths and science.”

“The F1 programme has also enabled students to gain more confidence as well as improve their time and resource management skills,” he said. “Team work has encouraged students’ on a journey of self-discovery. New career paths are being explored based on the various roles each student plays in the development of their F1 car.”

Mr Kgasoe said there is also more interest from other students who have seen the benefits from learning science and maths.” Mr Sangari added that the programme develops entrepreneurial skills in students who are required to research, prepare a business plan and build links with industry to gain sponsorship. Students gain first-hand experience in marketing and accounting as they need to provide a complete portfolio as part of the competition.

“The F1 competition focuses on blended learning through a cross curricula approach where learners physically apply what is learnt in the classroom. The true value lies in how learners take ownership of their own learning,” he said.

“What makes the F1 in Schools Technology Challenge different is that it entails a comprehensive and inclusive learning approach. Learners engage with subjects that improve their literacy, numeracy, sport and sports science, design and technology, art and design, textiles knowledge, STEM learning, computing, and business and enterprise,” concluded Mr Sangari.