Mechanical Rotating Solutions (MRS) Revolutionises Water Management in South African Mining Industry

Written by: Mario Smit Save to Instapaper

In the face of escalating water scarcity and rising costs, Mechanical Rotating Solutions, a leading provider of innovative mechanical sealing solutions has been at the forefront of cutting-edge technology to optimise water usage and enhance operational pump efficiency.

Water scarcity poses a significant challenge to the mining sector in South Africa, where the availability of water is crucial for mineral extraction processes. With large quantities of water indispensable for various stages of mining operations, effective water management becomes imperative. MRS acknowledges this pressing need and addresses it through the introduction of state-of-the-art mechanical seal systems, and water management solutions tailored specifically for the mining industry.

"The current water scarcity crisis in South Africa demands innovative solutions to ensure sustainable mining practices," says Franscois Steenkamp, CEO at Mechanical Rotating Solutions. "Our mission at MRS is to revolutionise water management in the mining sector by offering advanced mechanical sealing technology that not only enhances operational reliability but also significantly reduces water consumption."

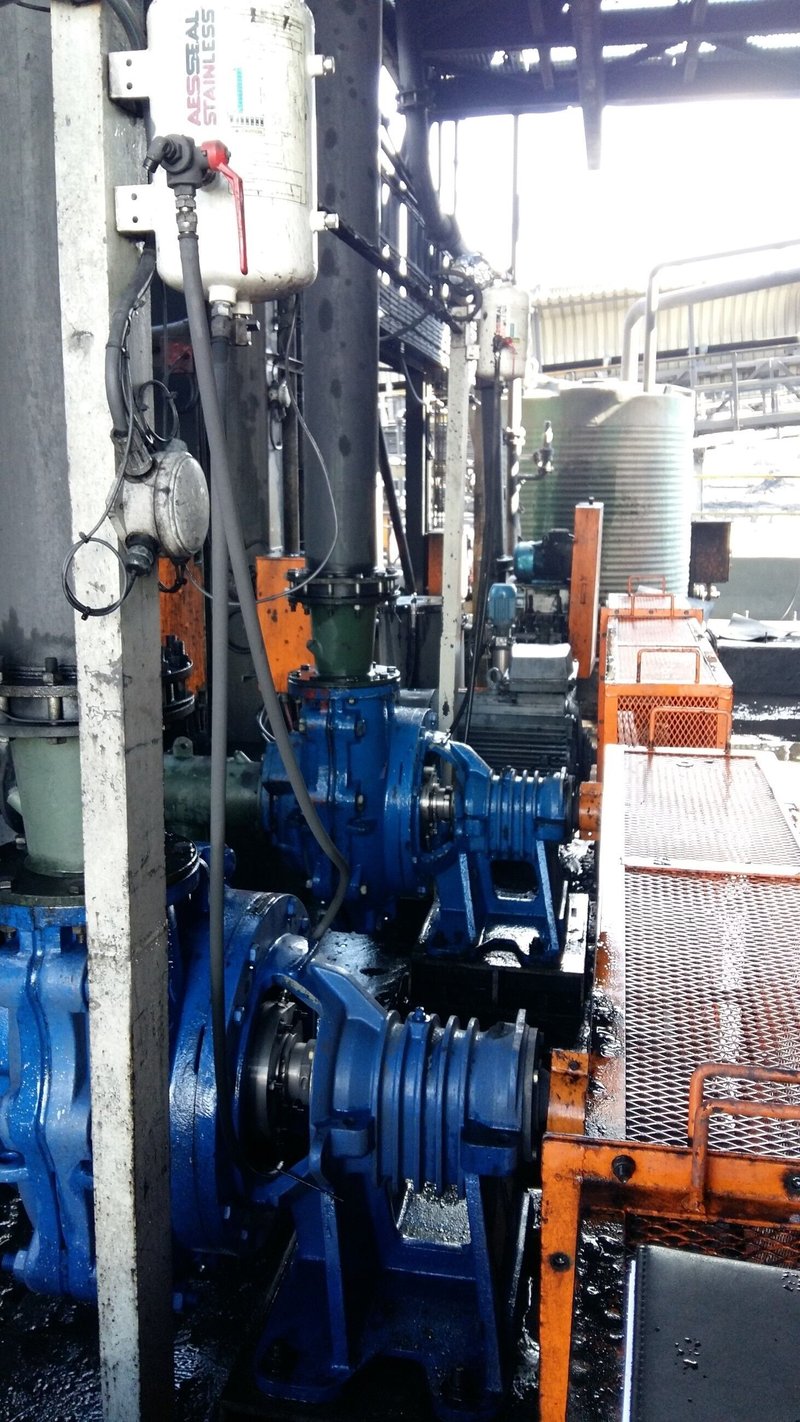

Pumps and related rotating equipment depend on seal water for optimal performance. Seal water serves three primary functions: cooling the seal and shaft, lubricating the seal, and purging impurities from the system. MRS's flagship product, the AESSEAL CDPH Heavy Duty Slurry Seals, has been successfully implemented in a recent project for a Mpumalanga colliery, showcasing remarkable results.

The coal mining industry in which MRS operates, is among the most challenging and costly sectors for the upkeep of pumps and associated rotating machinery. It not only contends with abrasive and corrosive environments but also grapples with the legacy of "run-to-failure" maintenance practices as well as operating in remote areas. Double mechanical seals and tank systems address all the issues linked with gland packing, offering a significant reduction in a mine's water usage footprint. Additionally, they diminish the need for manpower to maintain the pump’s gland packing, thereby enhancing the uptime and availability of the equipment.

“"Having been active across Mpumalanga for almost two decades in the coal mining industry, it is evident that the gland packing leakage rates are often more severe than anticipated. Many coal mining operations are overlooking opportunities to save costs, whether it's a question of pump packing gland adjustment skills, pump accessibility or inability to measure leakage.The leakage rate of normal functioning gland packing is always much higher than a properly selected mechanical seal accompanied by a seal support system. Having measured the leakage rate from properly installed gland packing the rate was recorded at approximately 5 to 8 litres per hour compared to approximately 0.1 litres per hour for high-pressure applications using a mechanical seal. So, over the course of a calendar year, the consumption would range from approximately 43,800 litres to 70,080 litres per pump! Although quantifying the exact loss of fluids due to various factors we have proved many times over that properly selected mechanical seals and seal support systems definitively reduce process fluid leakage. The long-term advantages, such as decreasing process fluid leakage and reducing ongoing maintenance expenses, can easily validate the initial investment of a mechanical seal and management system. When applied across a large number of pumps, the cumulative long-term savings in operational cost could prove substantial." Says Steenkamp.

The installation of the CDPH Heavy Duty Slurry Seals, coupled with the AESSEAL SW2 Water Management System, has led to lower power requirements, extended equipment lifespan, and minimised pump downtime. Moreover, the innovative fluid distribution unit (FDU) ensures optimal fluid management, utilizing filtration plant water lines to provide clean, cool, and stable water barrier fluid to the mechanical seals. Extensive studies by AESSEAL has shown that the environmentally friendly water management system have significantly contributed to the global drive for water conservation. This water management technology can save 6.3 Million litres of water per pump per year.

"The adoption of AESSEAL CDPH™ double mechanical seals, along with our fluid management systems, has not only optimized operational performance but also significantly reduced water consumption. With MRS's expertise and commitment to excellence, we aim to continue driving sustainability and efficiency in the mining industry."

Mechanical Rotating Solutions' dedication to innovation and sustainability is underscored by its extensive portfolio of mechanical sealing solutions, and related pump equipment servicing a wide range of pumps and rotating equipment throughout Sub Sahara Africa. With unparalleled client support and satisfaction, MRS remains at the forefront of pioneering advancements in water management for the mining sector.

Get new press articles by email

Latest from

- Mechanical Rotating Solutions Secures Major Straub Couplings Order for Mpumalanga Coal Processing Plant

- From Scarcity to Sustainability - Transforming Water Management in the Mining Industry

- Rapid ROI - Mechanical Seal Installation Delivers Impressive Savings

- Mechanical Rotating Solutions commissions four skid mounted Horizontal high pressure Centrifugal pumps

- Pump Technology - Navigating Net-Zero Strategies and Sustainable Water Management

- Mechanical Rotating Solutions mobile diesel pumps shows its worth

- Mechanical Rotating Solutions completes numerous new projects

- Better-then-new philosophy secures Mechanical Rotating Solutions Multiple Mobile Pump Orders

- Mechanical Rotating Solutions secures multiple mobile pump refurbishment contracts

- There is no substitute for Reliability and Return On Investment says mining supplies company Mechanical Rotating Solutions

- Mechanical Rotating Solutions adds to its flameproof product line

- Mechanical Rotating Solutions helps mining company to drastically reduce water wastage

- Demand for STRAUB pipe couplings sees rapid expansion into Africa

- Mechanical Rotating Solutions addresses long-coupled pump failure on Mpumalanga Coal mine

- Mechanical Rotating Solutions delivers turnkey gland water supply project

The Pulse Latest Articles

- Opinion Piece: Activating Leadership To Engage The Passive Workforce (February 11, 2026)

- Tchagra Trail Wilderness Consulting Launches A New Safari Experience In Photography And Tracking (February 9, 2026)

- Magic: The Gathering Releases Lorwyn Eclipsed (February 6, 2026)

- Back To Work, Back To Balance: Rethinking The 3pm Slump (February 5, 2026)

- Back-to-school Lunchboxes That Just Make Sense (February 5, 2026)