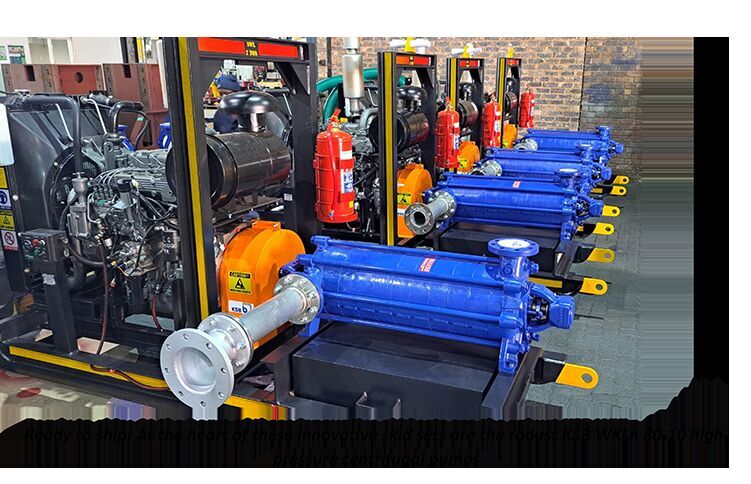

Mechanical Rotating Solutions commissions four skid mounted Horizontal high pressure Centrifugal pumps

Written by: Mario Smit Save to Instapaper

Mechanical Rotating Solutions (MRS) has once again demonstrated its engineering prowess by in-house designing and manufacturing four state-of-the-art mobile horizontal high pressure Centrifugal pumps pump sets on skids destined to the Horn of Africa. At the heart of these innovative skid sets are the robust KSB WKLn 80-10 high-pressure centrifugal pumps known for their durability and efficiency. This project marks a significant advancement in mobile pumping solutions offered by MRS’ adding this offering to the mining industry incorporating unparalleled flexibility, efficiency, and safety.

According to Franscois Steenkamp, CEO of Mechanical Rotating Solutions, the KSB WKLn 80-10 pumps used in these mobile skids are multistage horizontal high-pressure centrifugal pumps, featuring a sophisticated ring-section design. “These pumps boast radially split suction, discharge, and stage casings, with each component meticulously sealed by O-rings and secured with external tie bolts. The pump's design is further enhanced by integrally cast pump feet arranged beneath the suction and discharge casings, providing stability and durability when mounted on skids, even in the most challenging environments.”

Mechanical Rotating Solutions' mobile pump skid units offer a host of advantages that are particularly beneficial in the demanding conditions of mining operations:

The mobile nature of these units allows for rapid deployment and relocation across various site locations. This flexibility is crucial for adapting to the ever-changing needs and conditions of mining operations, such as adjusting to different phases or responding to unforeseen challenges. The ability to easily move these skids is especially valuable in remote or expansive mining sites, where logistical challenges can otherwise hinder operational efficiency. “By reducing the need for permanent infrastructure, these mobile skid units lower both initial capital expenditures and ongoing maintenance costs. This economic efficiency is further enhanced by the versatility of the equipment, allowing for repurposing and redeployment as needed, thereby maximizing asset utilization.” Says Steenkamp.

The skids can be quickly configured for a variety of tasks, including dewatering, slurry handling, and chemical dosing. This adaptability ensures that the right equipment is always at hand, minimizing downtime and ensuring seamless operations. The modular design also allows for easy upgrades or modifications, keeping pace with evolving operational needs. Also, safety is a paramount concern in mining, and the mobile pump skids excel in this regard. They can be repositioned to safer locations during blasting operations or moved to prevent environmental hazards. Additionally, in emergency situations like unexpected flooding, the skids can be rapidly deployed to mitigate damage, ensuring the safety of personnel and equipment.

The MRS designed skid systems streamline maintenance processes by allowing equipment to be brought to dedicated maintenance areas. This reduces the need for on-site servicing under potentially hazardous conditions, saving time and reducing costs. It also provides a safer and more controlled environment for maintenance personnel. The units include features designed to minimize environmental impact such as its mobility that allows for better management of environmental concerns, such as avoiding disruption to natural waterways by strategically positioning the equipment.

As mining projects grow or shrink, the scalability of these mobile pump skids becomes a significant advantage. They can be easily adjusted to match the scale of the operation, eliminating the need for substantial new infrastructure investments.

“Mechanical Rotating Solutions' new mobile pump skid units represent a significant leap forward in MRS’ mining offering as these units are set to become an indispensable asset in the mining industry offering, meeting the challenges of dynamic and demanding environments with ease. As the mining industry continues to evolve, Mechanical Rotating Solutions remains at the forefront, delivering innovative solutions that drive operational success.” Concluded Steenkamp.

Get new press articles by email

Latest from

- Mechanical Rotating Solutions Secures Major Straub Couplings Order for Mpumalanga Coal Processing Plant

- From Scarcity to Sustainability - Transforming Water Management in the Mining Industry

- Rapid ROI - Mechanical Seal Installation Delivers Impressive Savings

- Pump Technology - Navigating Net-Zero Strategies and Sustainable Water Management

- Mechanical Rotating Solutions (MRS) Revolutionises Water Management in South African Mining Industry

- Mechanical Rotating Solutions mobile diesel pumps shows its worth

- Mechanical Rotating Solutions completes numerous new projects

- Better-then-new philosophy secures Mechanical Rotating Solutions Multiple Mobile Pump Orders

- Mechanical Rotating Solutions secures multiple mobile pump refurbishment contracts

- There is no substitute for Reliability and Return On Investment says mining supplies company Mechanical Rotating Solutions

- Mechanical Rotating Solutions adds to its flameproof product line

- Mechanical Rotating Solutions helps mining company to drastically reduce water wastage

- Demand for STRAUB pipe couplings sees rapid expansion into Africa

- Mechanical Rotating Solutions addresses long-coupled pump failure on Mpumalanga Coal mine

- Mechanical Rotating Solutions delivers turnkey gland water supply project

The Pulse Latest Articles

- Opinion Piece: Activating Leadership To Engage The Passive Workforce (February 11, 2026)

- Tchagra Trail Wilderness Consulting Launches A New Safari Experience In Photography And Tracking (February 9, 2026)

- Magic: The Gathering Releases Lorwyn Eclipsed (February 6, 2026)

- Back To Work, Back To Balance: Rethinking The 3pm Slump (February 5, 2026)

- Back-to-school Lunchboxes That Just Make Sense (February 5, 2026)