Magnetic Solutions for Bulk Material Separation and Safety

Written by: Josh Maraney Save to Instapaper

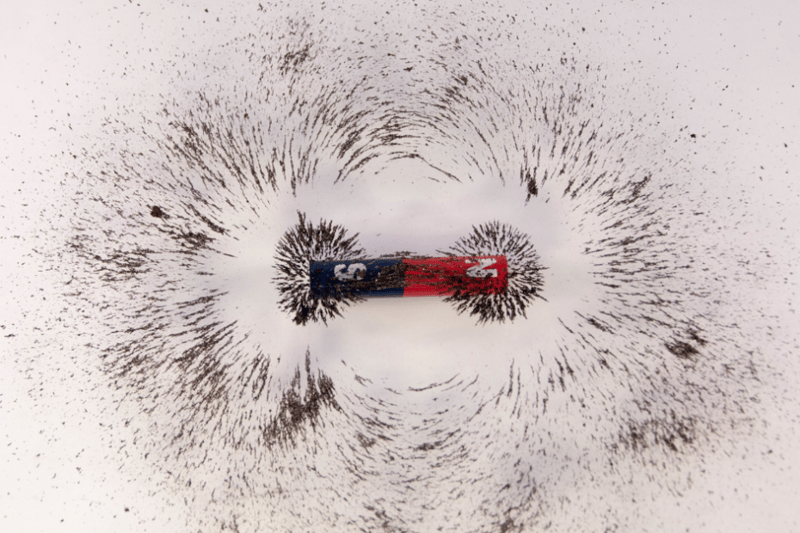

Magnetic equipment plays a major role in separating metals from other materials in different industries. Whether it’s mining, mineral processing, or handling of waste and raw materials, magnets are used to remove metal impurities, protect machinery, and improve output quality.

Using a Dry Magnetic Separator for Mineral Processing

A dry magnetic separator is often used where water is limited or not suitable for the process. These separators rely on air and magnetic force to pull magnetic materials like iron from non-magnetic ones. They’re common in mining environments where dust, rocks, and bulk minerals are moved in dry form.

In operations that handle crushed stone or coarse ores, a dry method reduces the risk of clogging and avoids the need for water handling infrastructure. This makes the separator both simple to install and easier to maintain in rugged field conditions.

The Role of Ferrochrome Magnets in Industry

A Ferrochrome Magnet is designed to separate or lift high-density chrome and iron alloys. These magnets are used in processes involving ferroalloys, especially in areas where the product contains mixed materials.

They help improve purity in final batches by removing unwanted metals or by sorting valuable pieces from waste. These magnets need to be strong enough to pull heavy and dense items without affecting lighter ones around them.

Iron Ore Beneficiation and Magnetic Separation

In mining, iron ore beneficiation is used to increase the iron content in ore while reducing impurities like silica and alumina. This process often includes crushing, screening, and magnetic separation.

By using magnets, the metal content in lower-grade ore can be increased. This makes it possible to make use of materials that would otherwise be too low-quality to process economically. It also cuts down on waste and reduces the volume of tailings that need to be stored or discarded.

Coal Beneficiation and Tramp Removal

Coal beneficiation improves the quality of coal by removing unwanted materials like stones, sulphur, and metal bits. In coal plants, magnets are used to pull out metal scraps before crushing or burning takes place.

This protects crushers and conveyor belts from damage. It also improves the quality of the final fuel by reducing ash content. In many coal handling setups, suspended magnets and magnetic pulleys are positioned along the conveyor to intercept metal at different stages.

Material Handling Magnets in Large-Scale Operations

When moving raw materials, scrap, or sorted metals, material handling magnets are used to lift and shift metal-heavy loads. These magnets help reduce labour, speed up sorting, and lower the risk of injury.

They’re common in scrapyards, steel plants, and shipping yards where bulk metal must be moved safely and quickly. Some magnets are powered, while others use permanent magnets that don’t need electricity.

Benefits of Mining Magnets

Mining magnets help with both product quality and safety. They can be installed at different points in the mining flow, including crushers, screens, and transfer points.

These magnets reduce downtime caused by metal jams or broken parts. They also help improve the value of the mined product by removing unwanted iron or steel.

Suspended Conveyor Magnet for Tramp Metal

A suspended conveyor magnet hangs above a conveyor belt and captures metal before it enters crushers or screens. These units are ideal for fast-moving lines and large belts.

This type of magnet is fixed in place and needs little manual input. Once installed, it works continuously to remove tramp metal and protect equipment downstream.

Suspended Magnetic Separator in Heavy Lifting

A suspended magnetic separator is similar to a conveyor magnet, but is often larger and used for lifting bulk items. These are common in ports, loading docks, and steel plants.

The separator is designed to pull metal out from mixed materials, either for disposal or recovery. It can be used to sort metals or to clean up after demolition or heavy construction work.

How Tramp Magnets and Tramp Metal Magnets Work

A tramp magnet is designed to catch metal that should not be in the production line. This includes nails, bolts, tools, or scrap that might fall into the conveyor or mixer.

Tramp metal magnets work by pulling unwanted ferrous items out of product flow. These can be placed before grinders, mills, or screens to reduce damage and improve output.

Submitted on behalf of

- Company: afrimags

- Contact #: 0828881687

- Website

Press Release Submitted By

- Agency/PR Company: Top click

- Contact person: Josh Maraney

- Website

Get new press articles by email

Top Click is one of South Africa’s leading full-service digital marketing agencies. Our custom-built, cutting-edge solutions are targeted to help you attract customers, convert leads and grow your business. From SEO and Google Ads to social media marketing and digital design, our measurable marketing campaigns deliver results – and ensure that, in a cluttered online marketplace, you rise... Read More

Latest from

- Choosing the Right Pet Food for Your Animals

- Managing Contracts With Simpler Tools

- New Website to Keep Up with the Demand for Online Pet Food Delivery in South Africa

- Machines That Make Packaging Easier

- The Role of Transit Solutions in Modern Connectivity

- How to Get Cheaper Car Insurance Without the Stress

- Making Radiology Workflows Simpler with the Right Tools

- Reduce Late Payments with These Practical Tips

- A Simple Guide to Choosing the Right Forklift for Your Business

- Keeping Your Car in Good Shape with the Right Services

- Why Property and Asset Valuations Matter

- Finding Quality Engines and Scrap Yard Services

- Practical Guide to Rooftop Tents

- Practical Uses of Vehicle Awnings

- A Look at Engine Choices Across Popular Car Brands

The Pulse Latest Articles

- Celebrating 125 Years Of Hansgrohe: Setting The Beat Of Water Since 1901 (February 25, 2026)

- Celebrate Pokémon Day At Toys R Us Menlyn On 28 Feb (February 25, 2026)

- The Great Generational Handover: Why South Africa’s Middle Managers Are The Hinge Of 2026 (February 23, 2026)

- Jennifer Hadley Photography Announces A Curated 2026 Katmai Bear Photography Season (February 18, 2026)

- Life Doesn’t Have To Be A Lot – The In-between Drink (February 17, 2026)