Magnetic Equipment Used in Processing and Material Recovery

Written by: Josh Maraney Save to Instapaper

Magnetic systems help with separating, lifting, and protecting. They are used in mining, recycling, construction, and mineral processing. Their purpose is simple—remove unwanted metal or recover metal that has value. These tools have made material sorting faster, more accurate, and safer.

Dry Magnetic Separator Use in Processing Plants

A dry magnetic separator works without water. This is ideal for sites where water is expensive or not available. It’s commonly used in dry mineral handling, separating ferrous material from non-magnetic matter.

These separators are often used before crushing or screening. The main goal is to clean up the feed and protect machinery. They also help reduce dust and improve product quality.

Ferrochrome Magnet for High-Density Alloys

The Ferrochrome Magnet is made for one purpose—to pick up or remove ferrochrome pieces. These are high-density alloys used in steel and smelting industries.

When ferrochrome is mixed with other materials, a strong magnet is needed to lift or separate it. This type of magnet is useful in quality control or recovery of expensive metal that could otherwise be lost in waste.

Iron Ore Beneficiation and Magnetic Support

Iron ore beneficiation involves removing silica, clay, and other waste from raw ore. Magnetic separation plays a big role in this. Strong magnets pull iron-rich particles out of the feed, making the ore more valuable.

In lower-grade ore, magnetic removal helps boost metal yield. This reduces the need for chemical methods and cuts waste. It’s also helpful in sorting operations at mining plants.

Coal Beneficiation and Contaminant Removal

During coal beneficiation, rocks and other heavy waste are removed to improve energy output. Magnets are often used to clean the product before it goes to the boiler or crusher.

Scraps like nails, metal rods, and tools can damage machines or reduce fuel quality. Using magnets at early stages keeps the process clean and cost-efficient.

Material Handling Magnets in Scrap and Steel Yards

Material handling magnets are common in busy yards, mills, and waste plants. They are used to lift, drop, or move large chunks of metal like beams, plates, or scrap.

They reduce labour costs and improve safety. These magnets can also help sort reusable metal from rubbish. Some systems are permanent, while others are powered and can be switched off when not in use.

Mining Magnets for Separation and Equipment Protection

Mining magnets are added to belt conveyors and chutes to catch any tramp metal. They protect crushers, grinders, and screens from damage. This saves downtime and lowers maintenance costs.

They are also used to remove iron-rich rocks that don’t belong in the final product. These can appear during loading or blasting. Magnets offer an easy fix by pulling out the metal before it reaches the final processing line.

Suspended Conveyor Magnet and Its Role

A suspended conveyor magnet is placed above a moving belt. It picks up metal objects before they can go through crushers or hoppers. This system works well in fast-moving or high-volume lines.

The magnet runs all day without needing adjustments. It acts like a safety filter. Even small bolts or sharp objects can break equipment, so these suspended units are worth installing early.

Suspended Magnetic Separator for Heavy-Duty Jobs

A suspended magnetic separator does more than just protect machines. It’s also used to sort and recover metal in industrial plants.

In recycling or demolition, the separator pulls large items like car parts, rebar, and metal beams from concrete and rubble. It’s often part of a mobile system used at temporary sites or landfills.

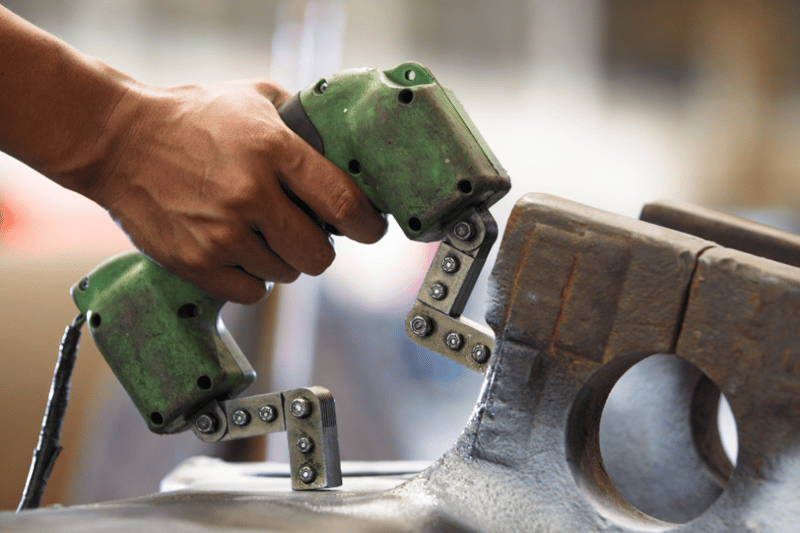

Tramp Magnet for Metal Detection and Removal

A tramp magnet is designed to catch unwanted metal. These include dropped tools, fasteners, or wires that slip into the production line.

Placed above or beside material flow, the magnet works as a safety net. It helps prevent breakdowns and improves overall product quality by keeping the line free of harmful scraps.

How Tramp Metal Magnets Improve Plant Safety

Tramp metal magnets are found in cement plants, power stations, and factories. Their role is to protect machines and people. When metal ends up in the mix, it can cause serious damage.

Magnets provide a simple fix—no need for complex sensors or cameras. They work by force alone and help reduce repairs, injuries, and delays.

Submitted on behalf of

- Company: Afrimags

- Contact #: 0828881687

- Website

Press Release Submitted By

- Agency/PR Company: Top click

- Contact person: Josh Maraney

- Website

Get new press articles by email

Top Click is one of South Africa’s leading full-service digital marketing agencies. Our custom-built, cutting-edge solutions are targeted to help you attract customers, convert leads and grow your business. From SEO and Google Ads to social media marketing and digital design, our measurable marketing campaigns deliver results – and ensure that, in a cluttered online marketplace, you rise... Read More

Latest from

- Choosing the Right Pet Food for Your Animals

- Managing Contracts With Simpler Tools

- New Website to Keep Up with the Demand for Online Pet Food Delivery in South Africa

- Machines That Make Packaging Easier

- The Role of Transit Solutions in Modern Connectivity

- How to Get Cheaper Car Insurance Without the Stress

- Making Radiology Workflows Simpler with the Right Tools

- Reduce Late Payments with These Practical Tips

- A Simple Guide to Choosing the Right Forklift for Your Business

- Keeping Your Car in Good Shape with the Right Services

- Why Property and Asset Valuations Matter

- Finding Quality Engines and Scrap Yard Services

- Practical Guide to Rooftop Tents

- Practical Uses of Vehicle Awnings

- A Look at Engine Choices Across Popular Car Brands

The Pulse Latest Articles

- Celebrating 125 Years Of Hansgrohe: Setting The Beat Of Water Since 1901 (February 25, 2026)

- Celebrate Pokémon Day At Toys R Us Menlyn On 28 Feb (February 25, 2026)

- The Great Generational Handover: Why South Africa’s Middle Managers Are The Hinge Of 2026 (February 23, 2026)

- Jennifer Hadley Photography Announces A Curated 2026 Katmai Bear Photography Season (February 18, 2026)

- Life Doesn’t Have To Be A Lot – The In-between Drink (February 17, 2026)